2021-2022

Ongoing Development : Patterning, Manufacturing and Finishing Systems for Performance Fabrics

|

|

2022

|

2021

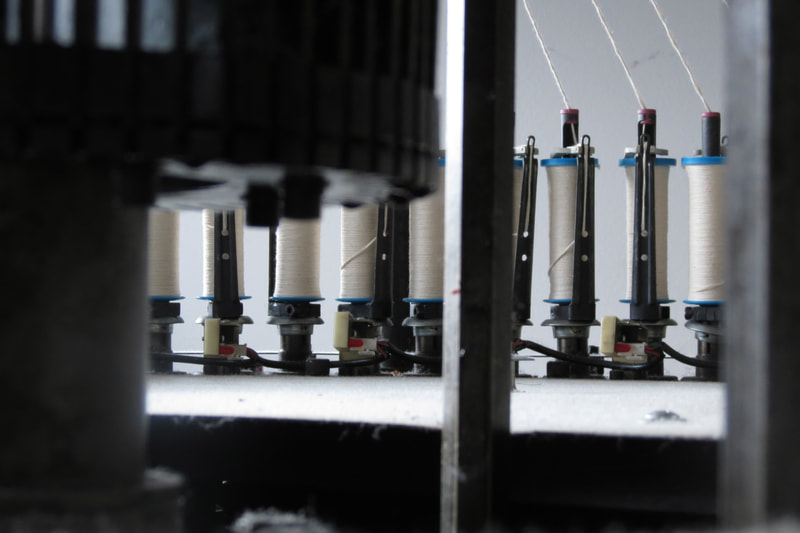

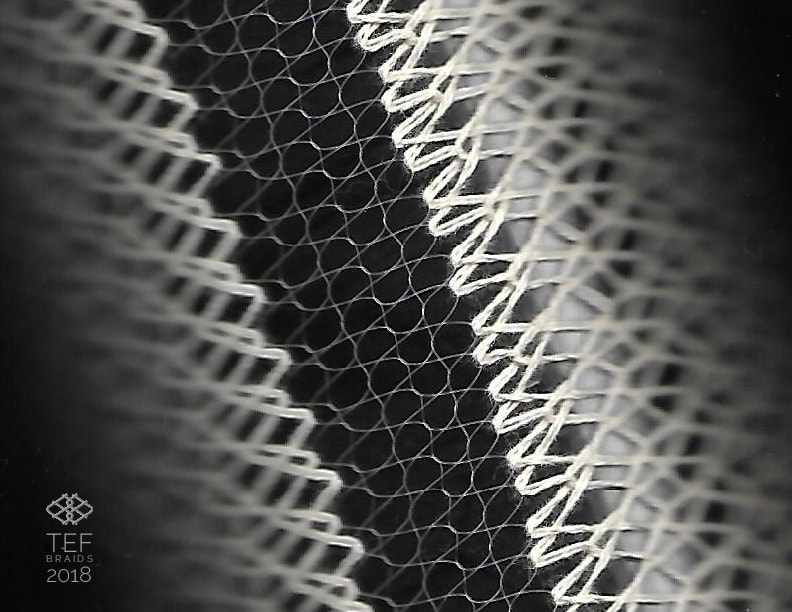

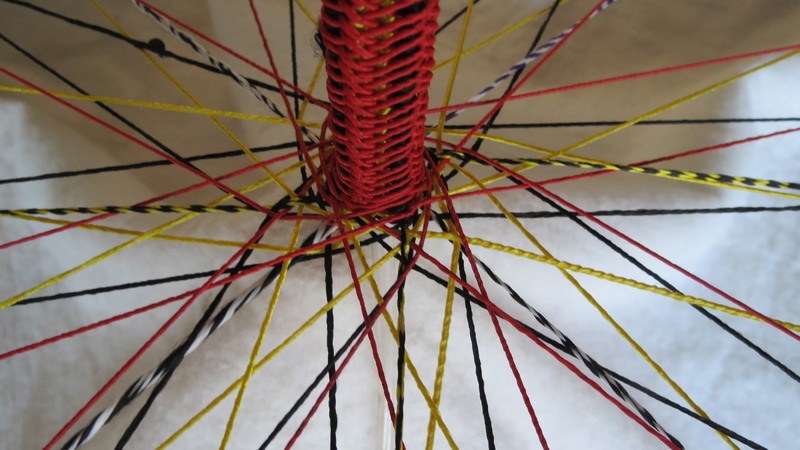

Our new lace braiding machines arrived at TEF Braids USA factory in Athol, New York, from Xuzhou Dongmai Trading Co., LTD in Xuzhou, China on Tuesday the 3rd of August, 2021. We would like to thank everyone at Xuzhou who helped create and deliver such fine machinery and Curtis Lumber of Warrensburg, New York, who assisted with their forklift to unload the the two ton boxes.

|

|

2020

|

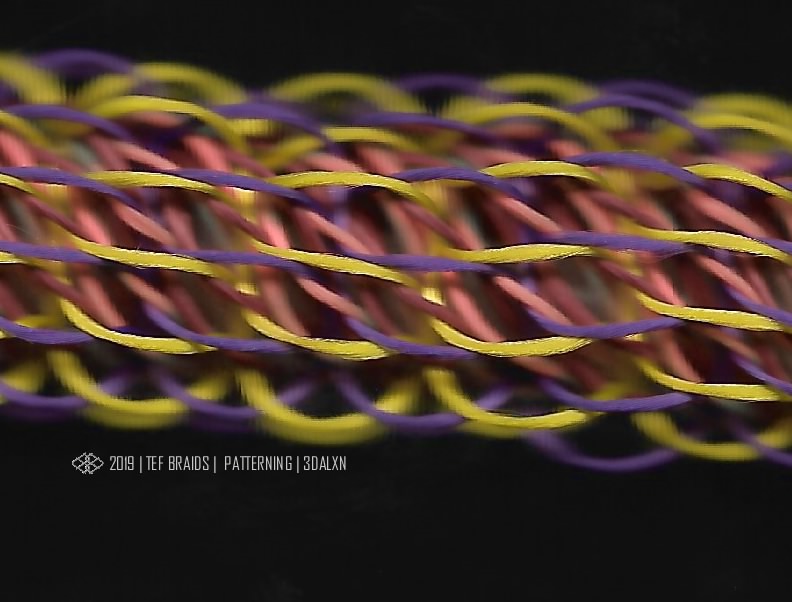

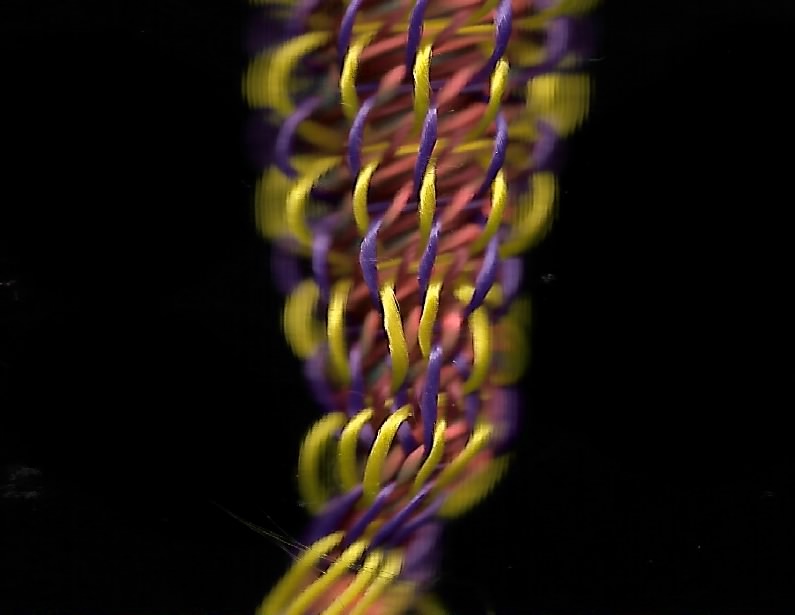

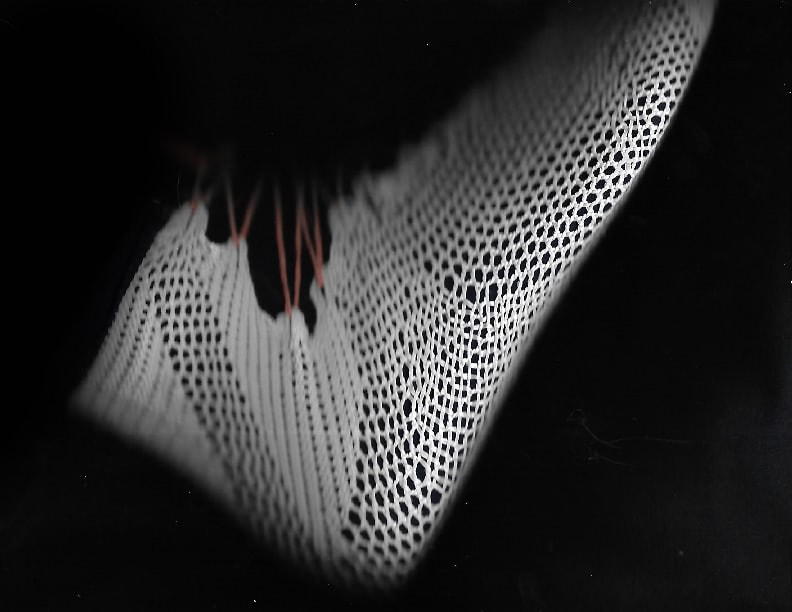

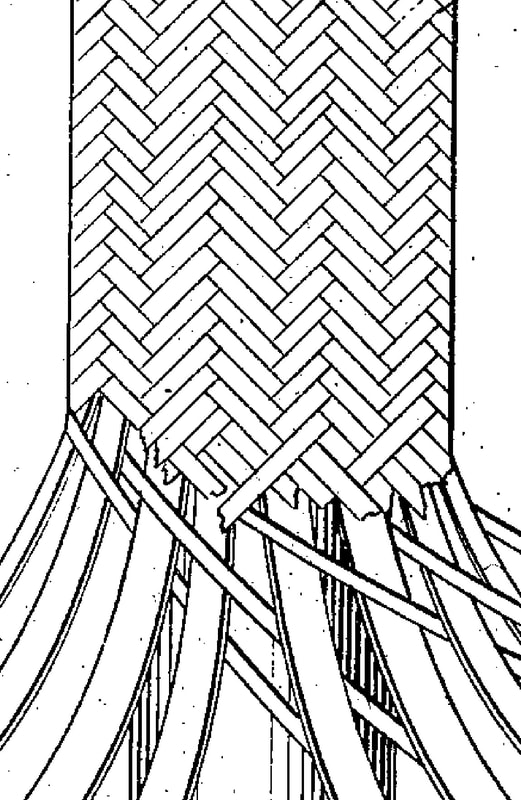

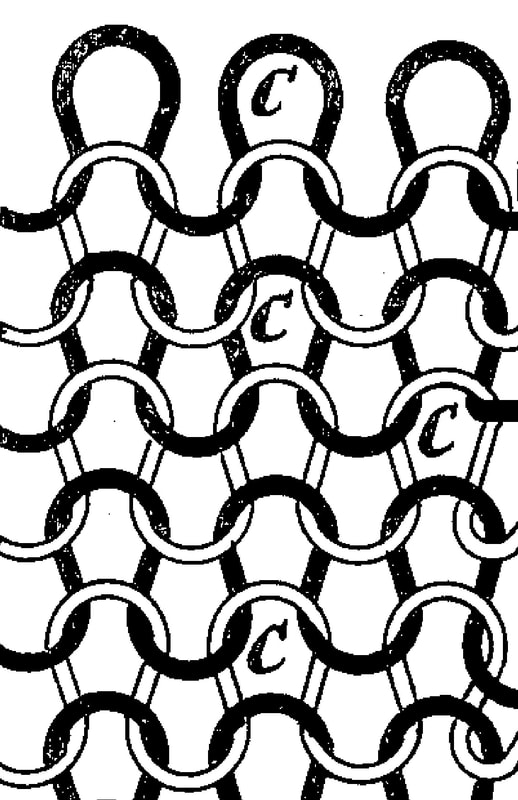

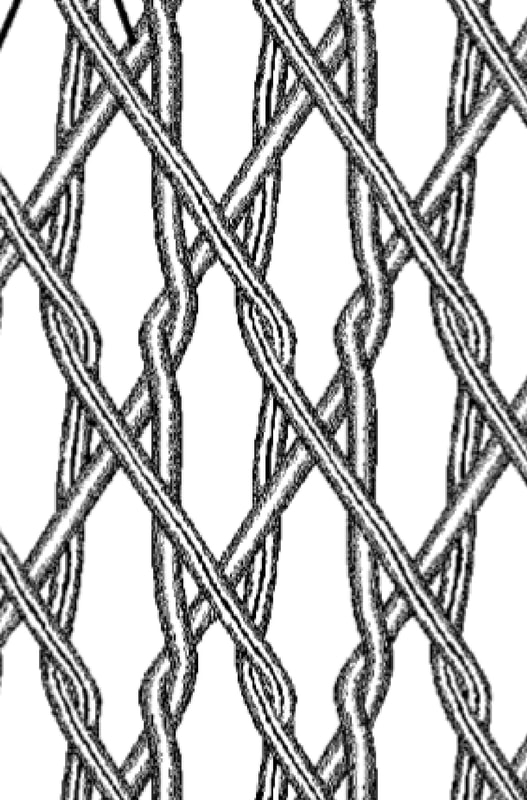

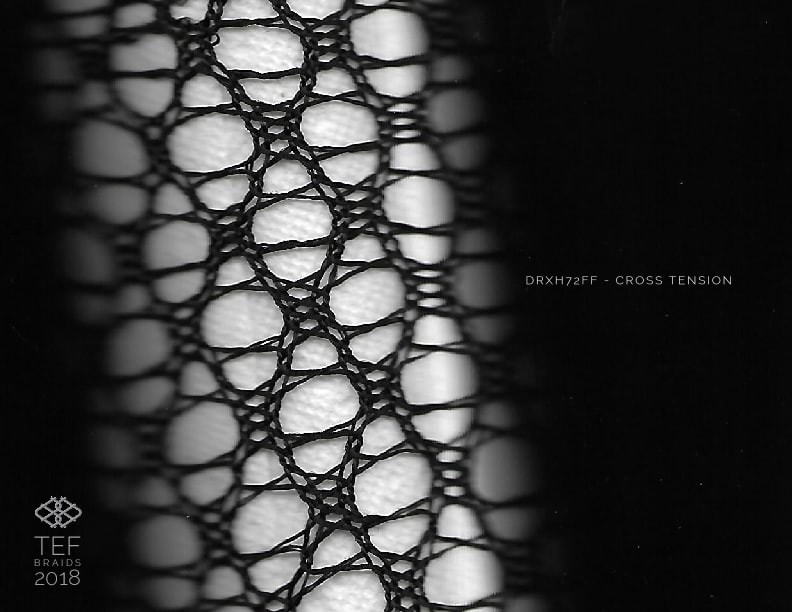

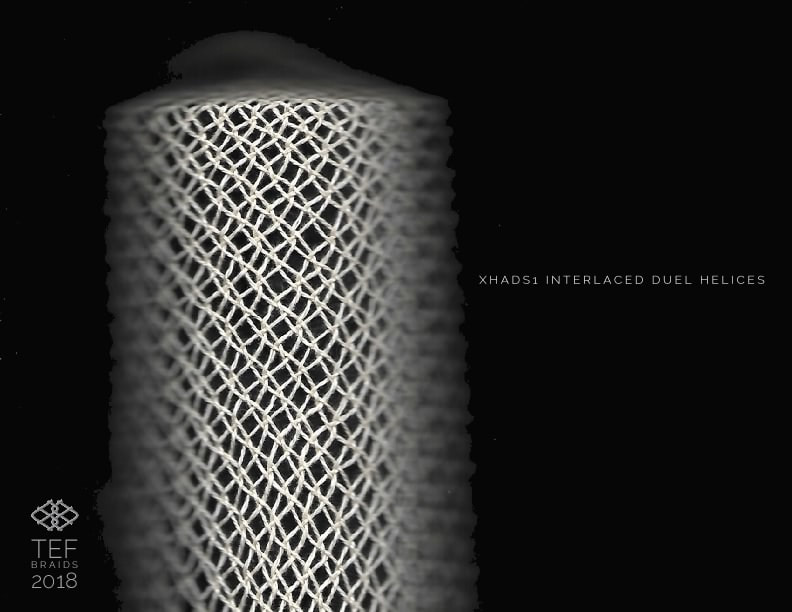

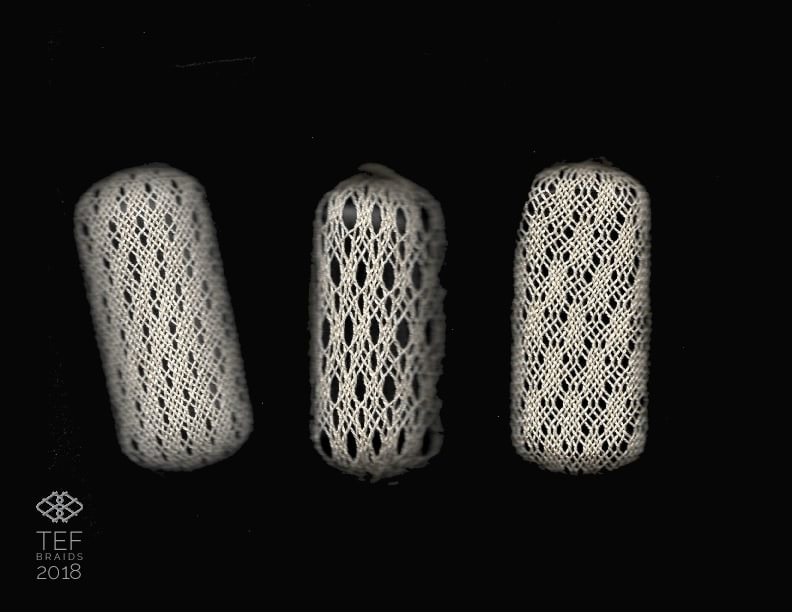

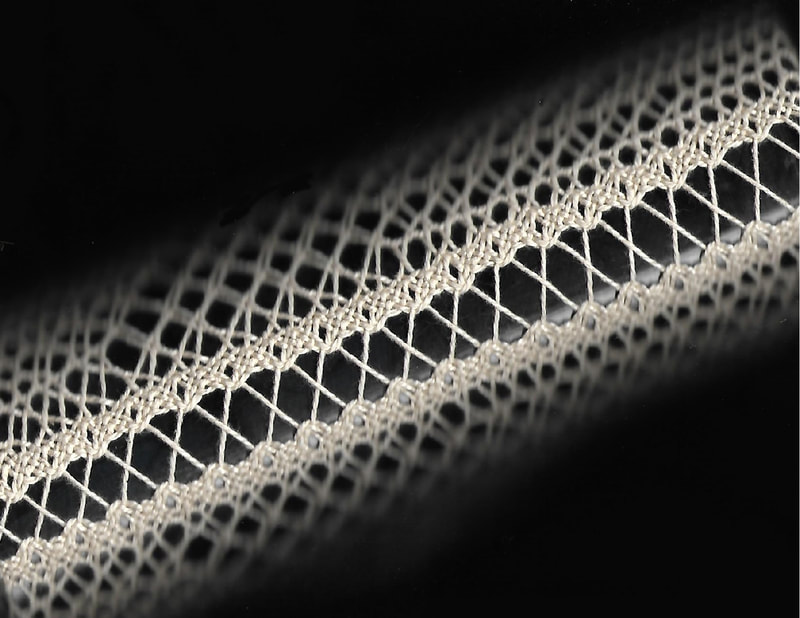

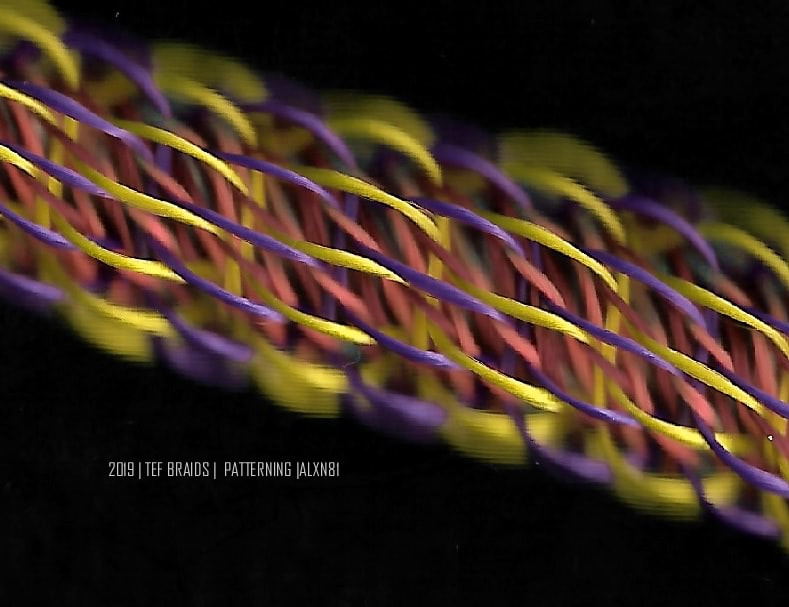

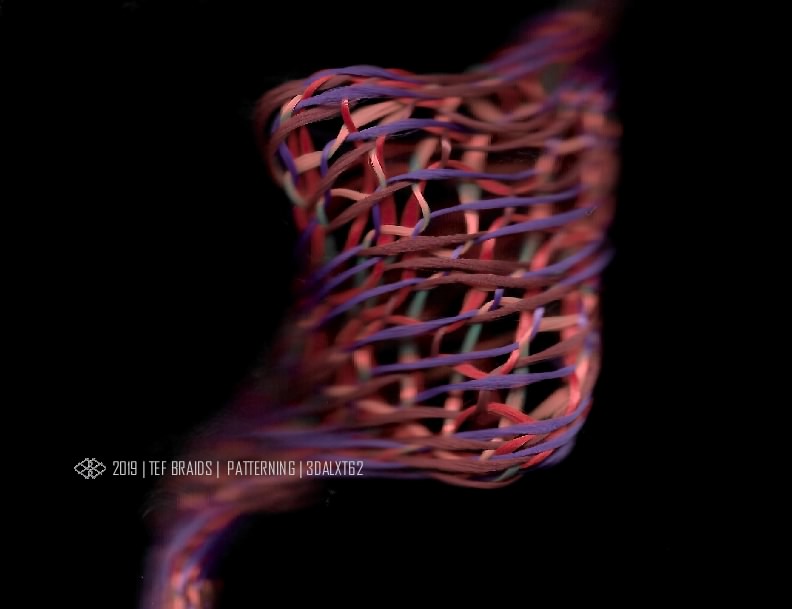

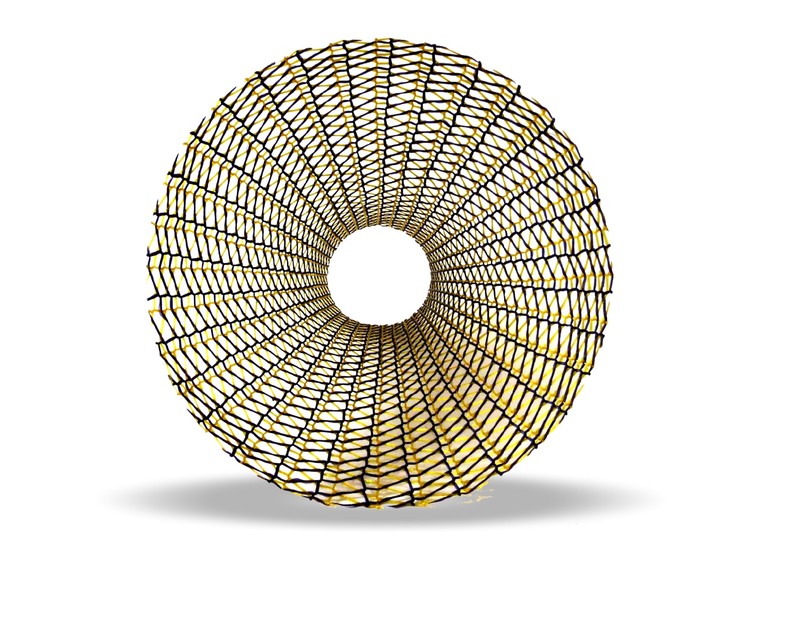

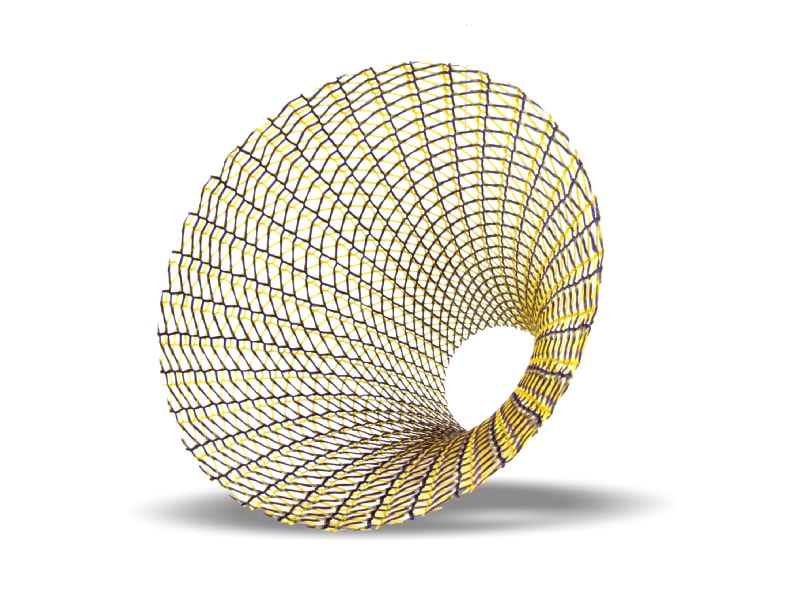

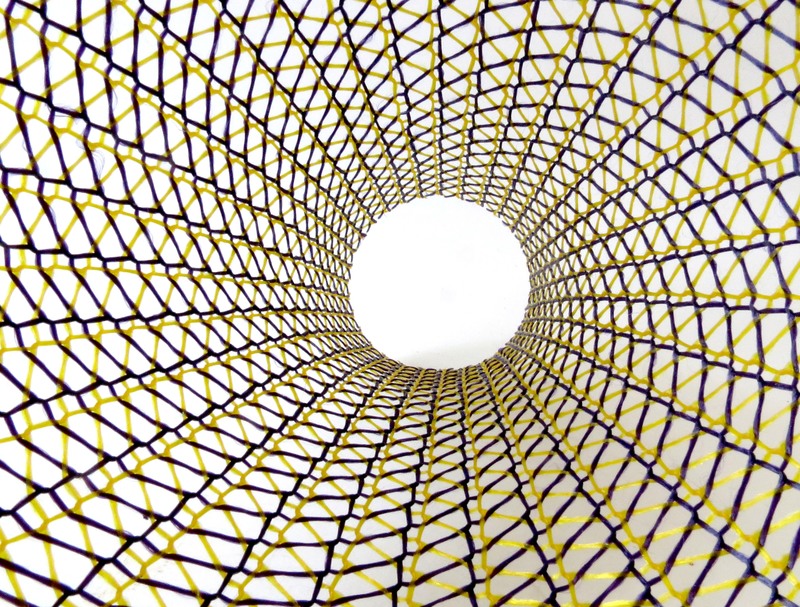

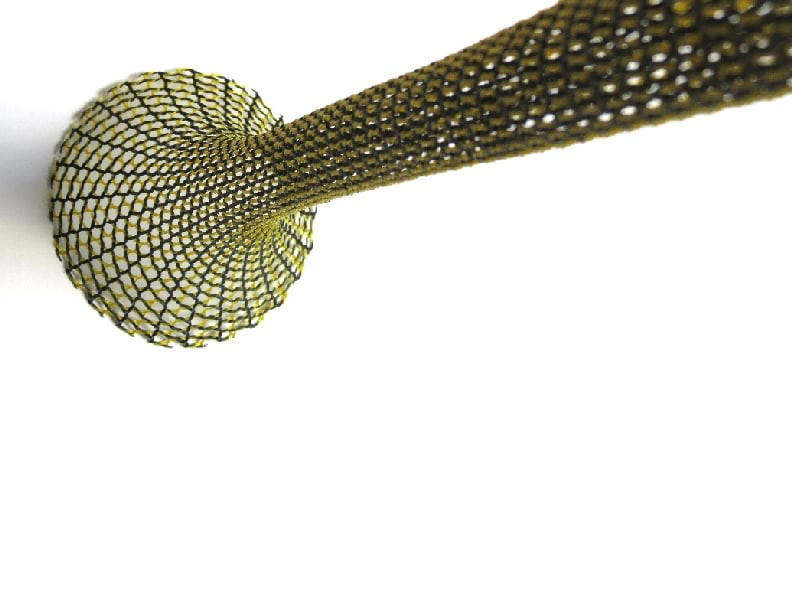

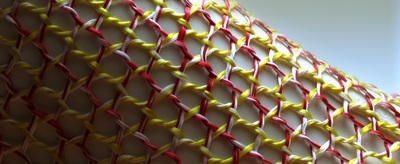

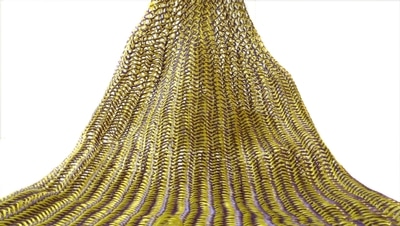

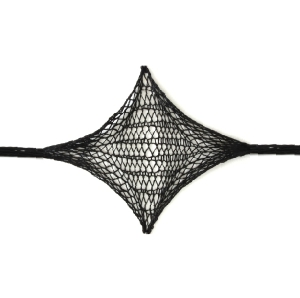

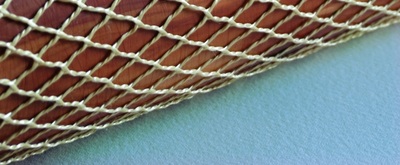

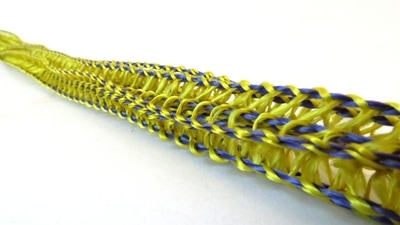

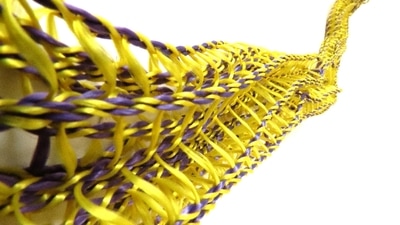

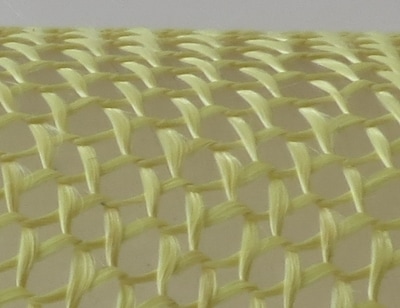

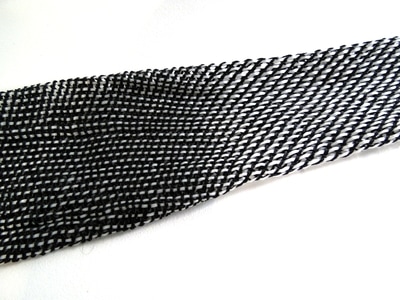

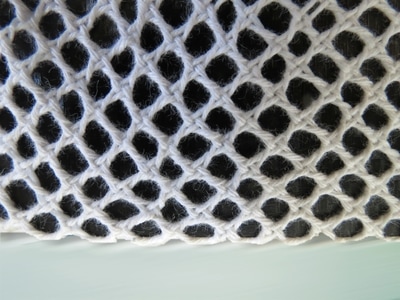

HYBRAID BRAID

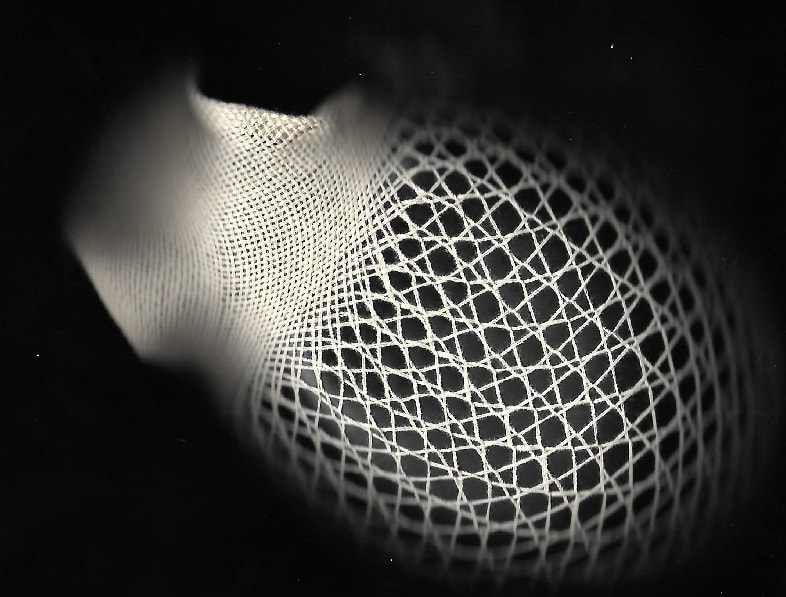

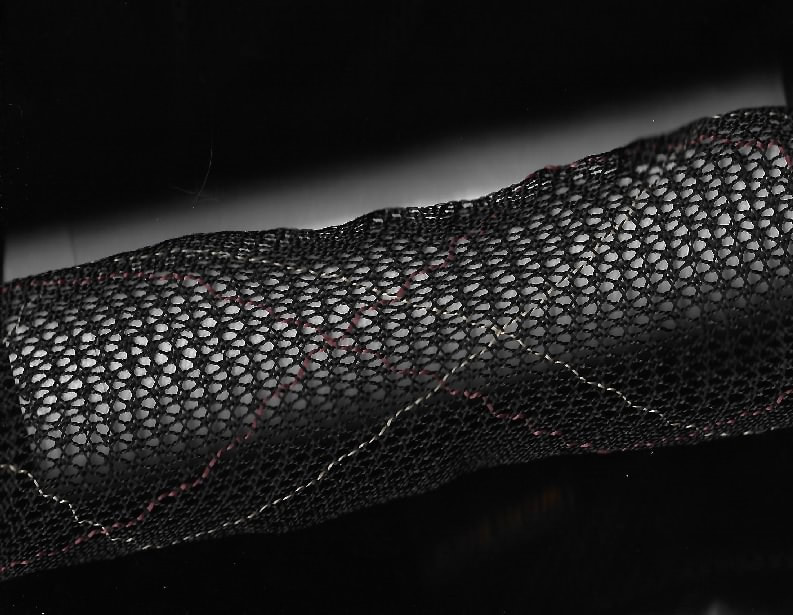

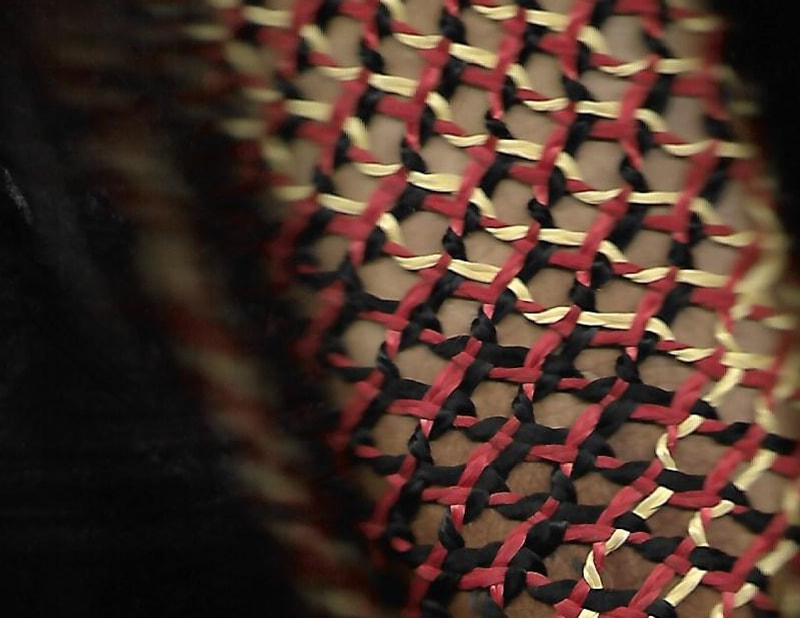

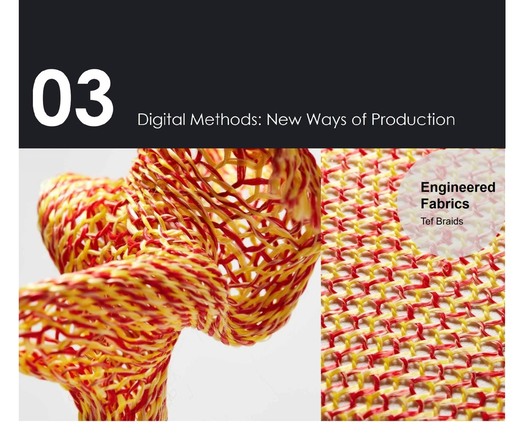

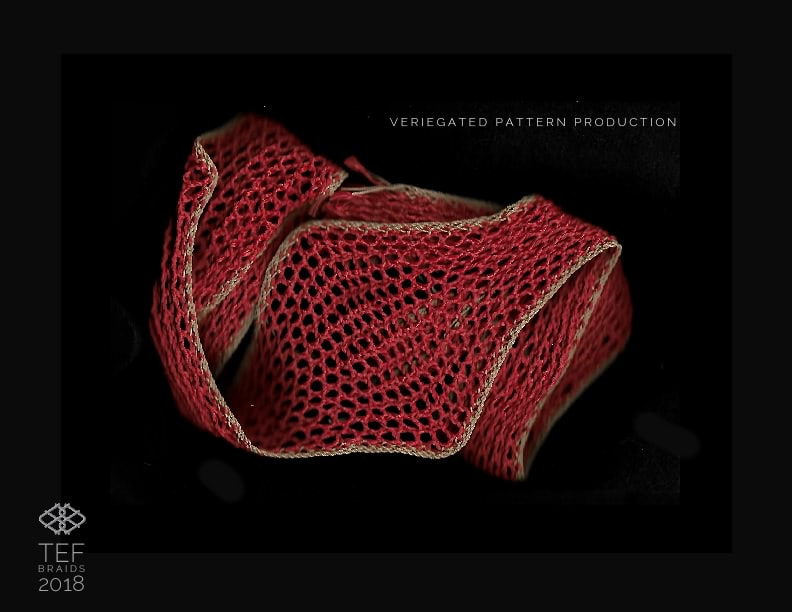

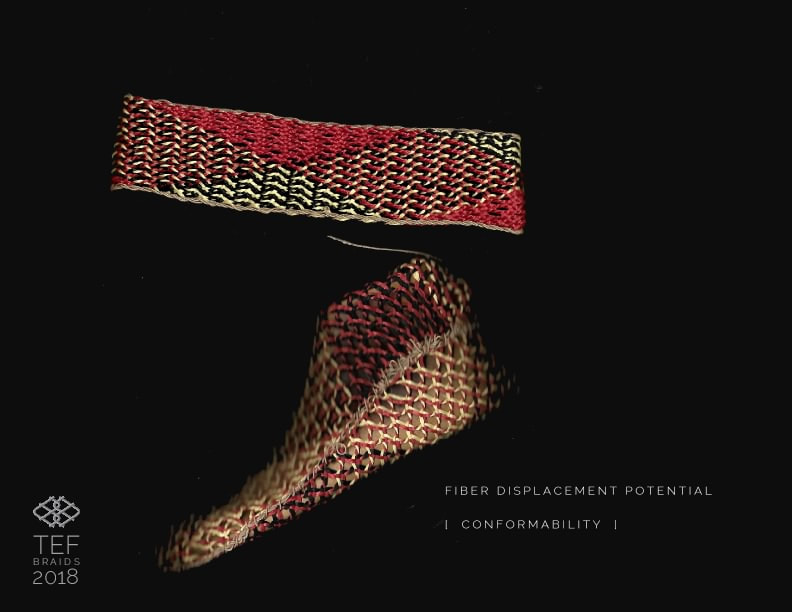

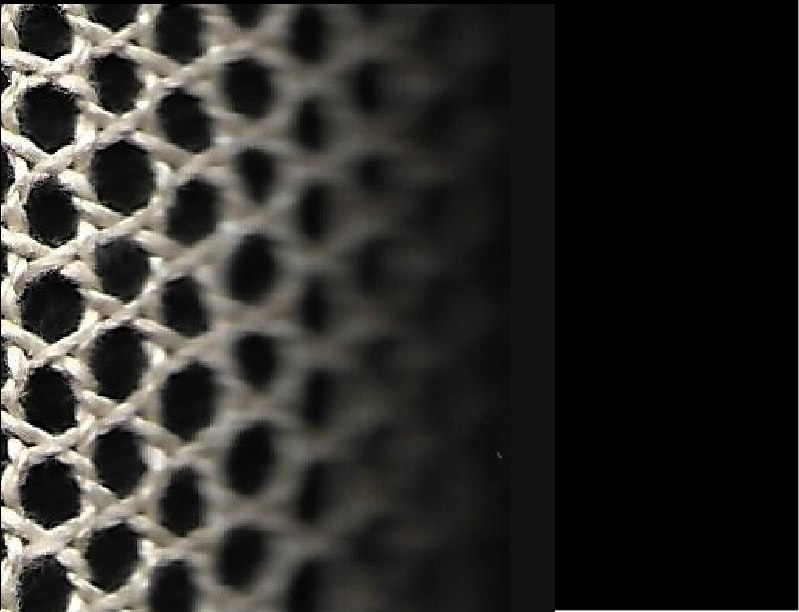

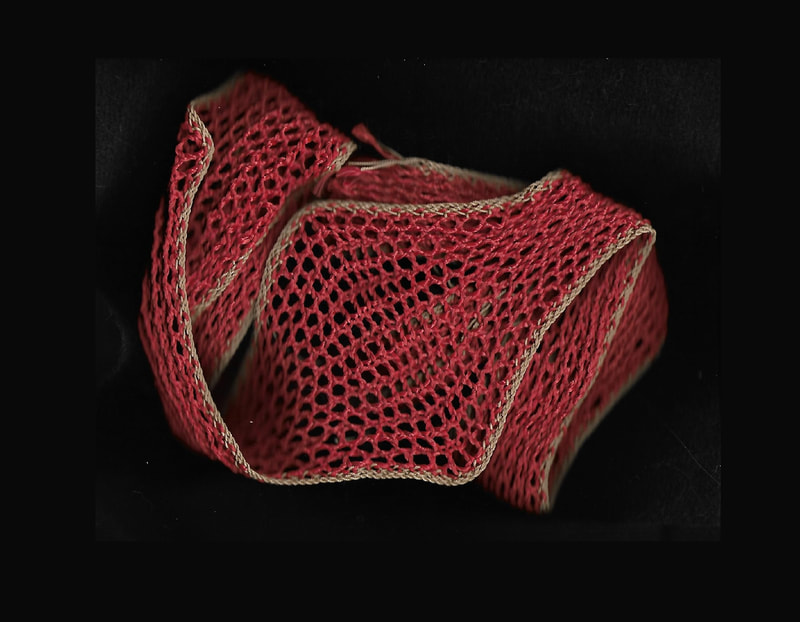

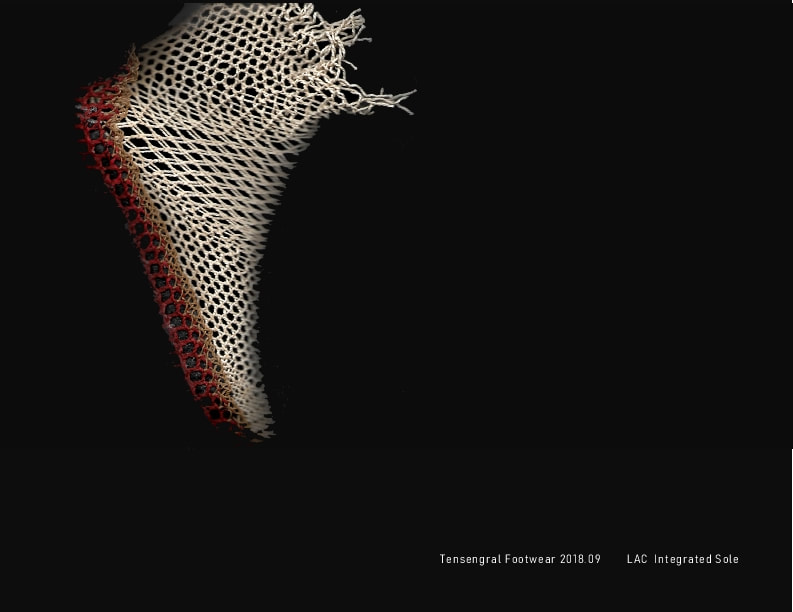

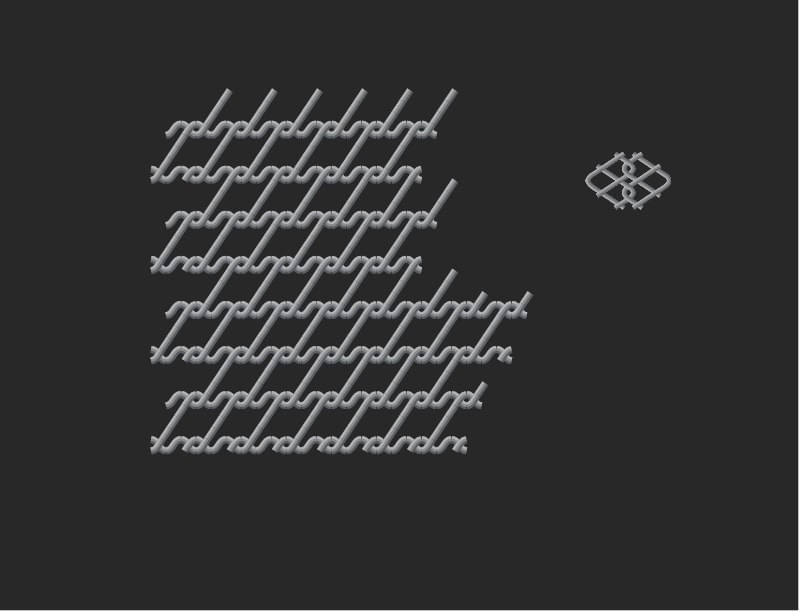

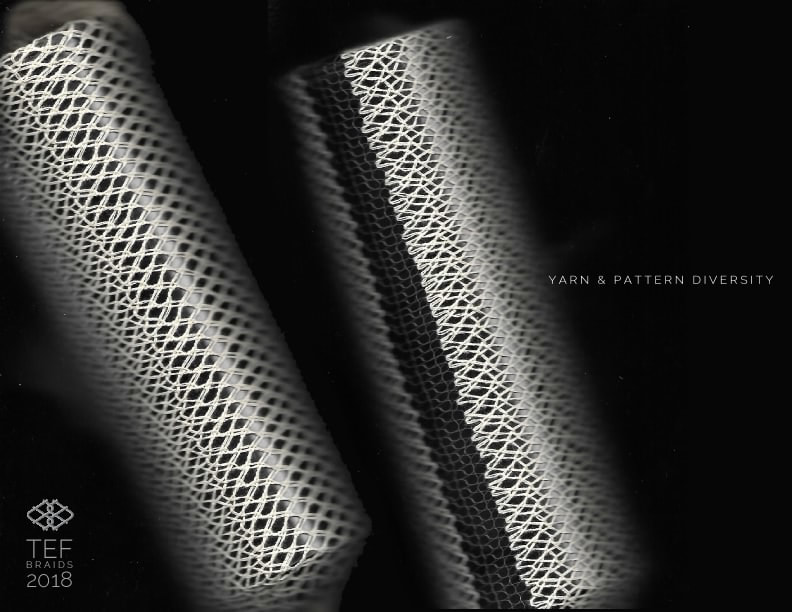

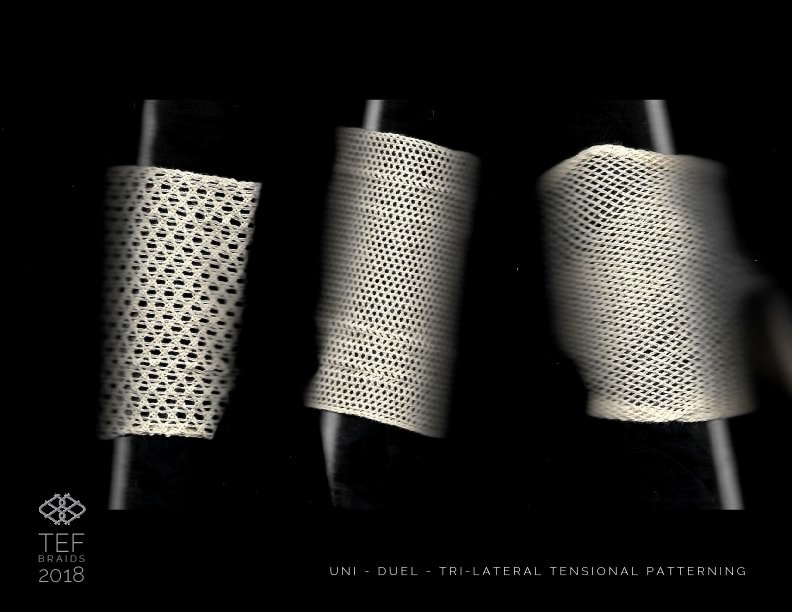

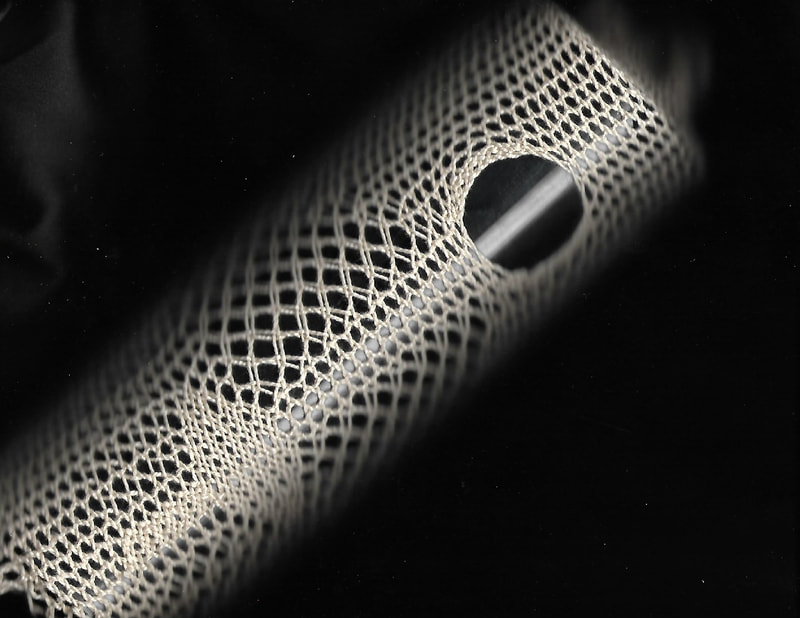

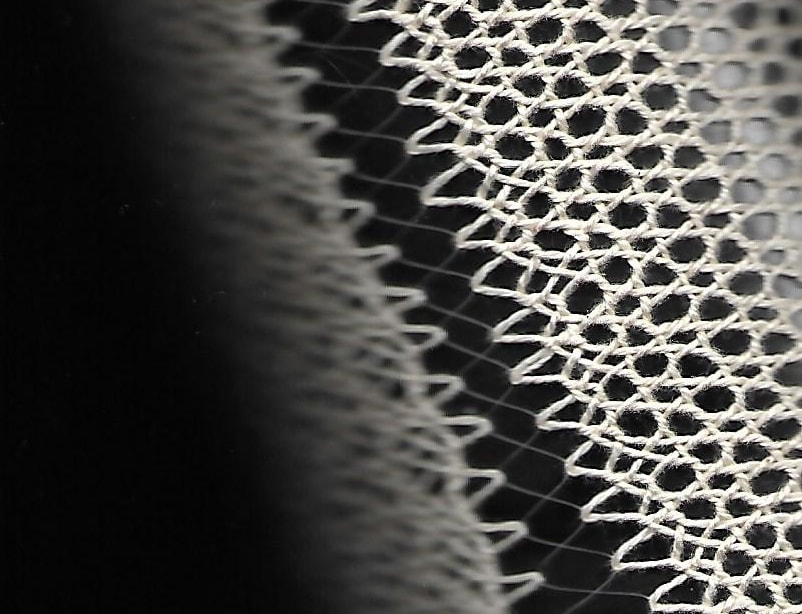

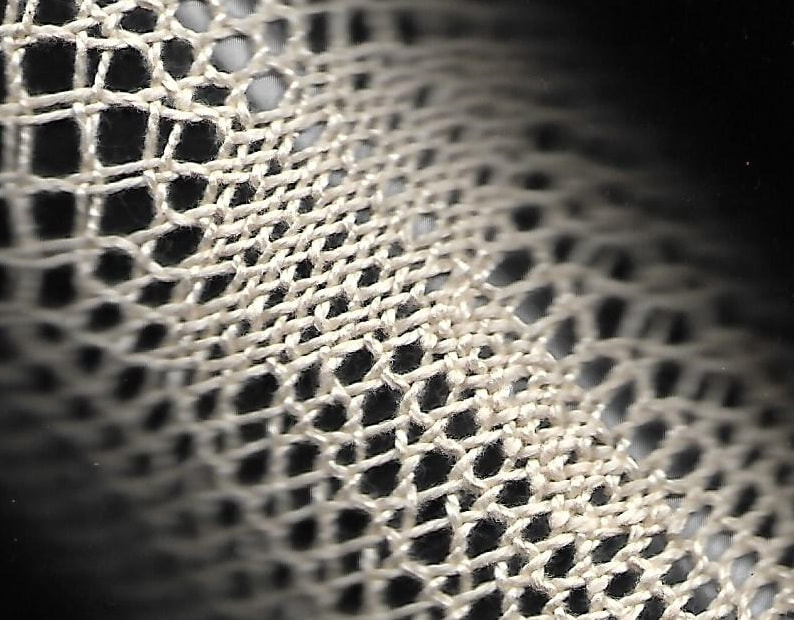

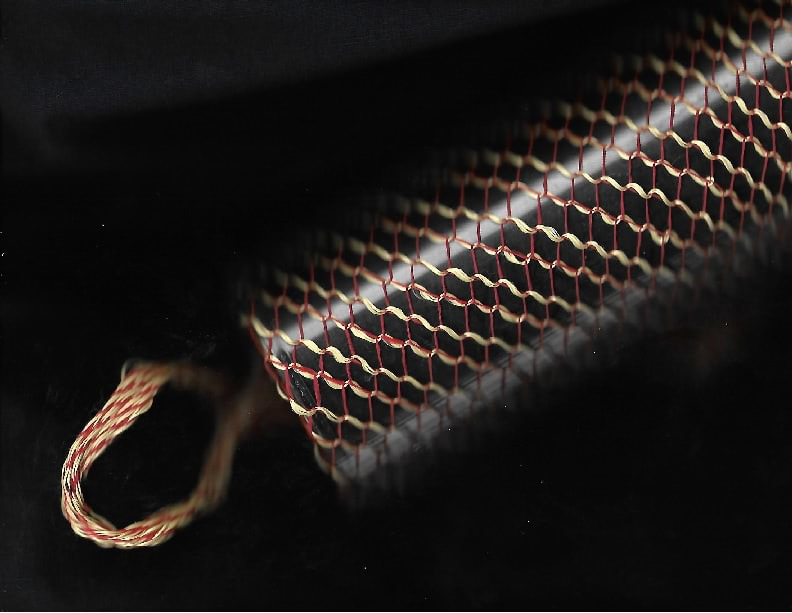

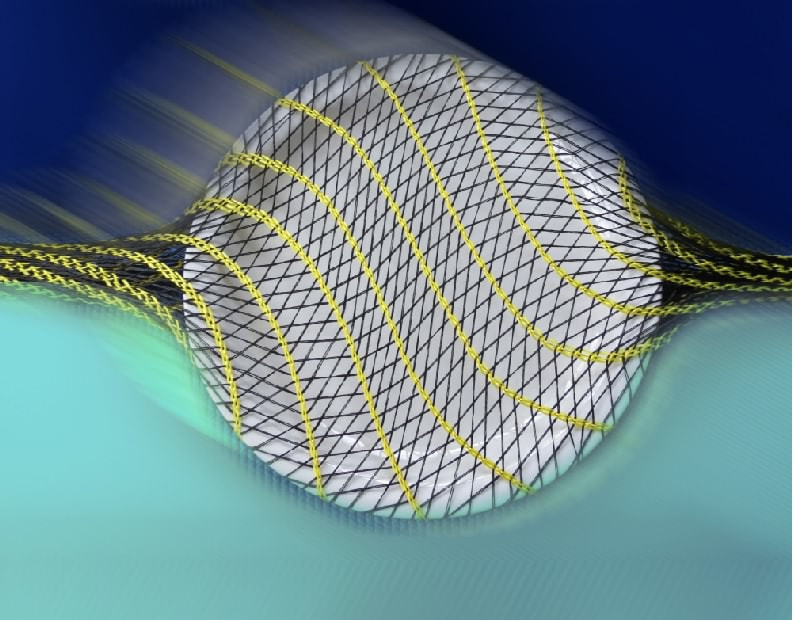

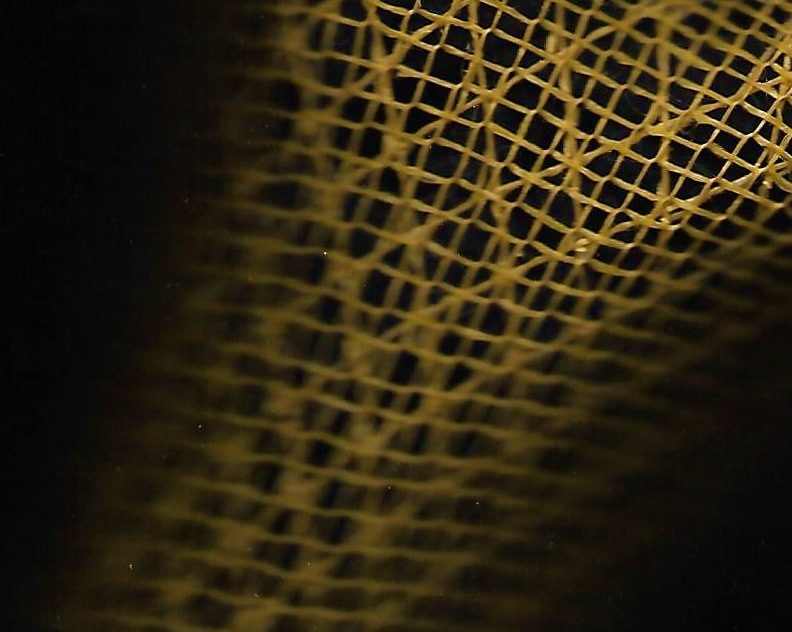

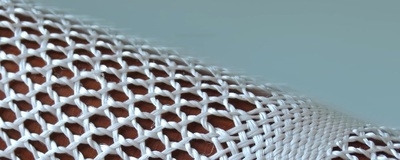

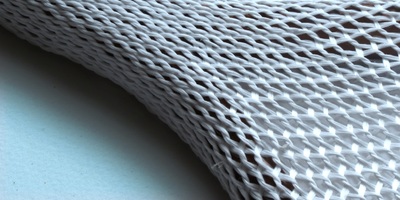

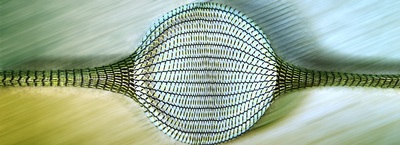

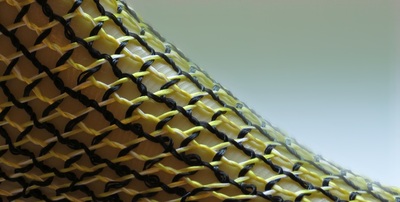

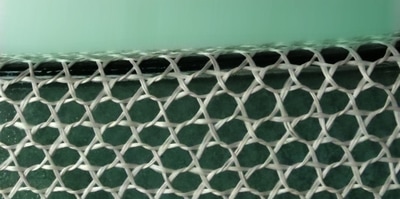

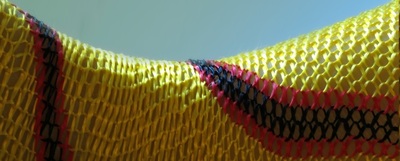

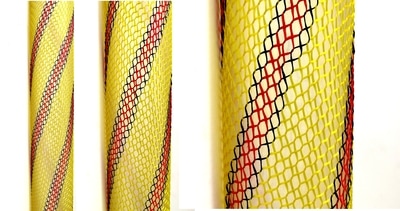

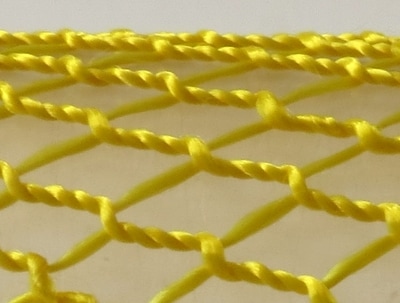

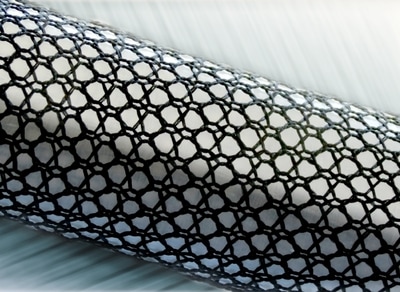

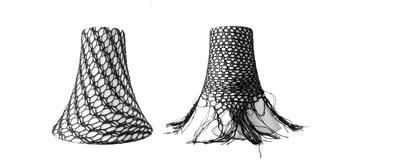

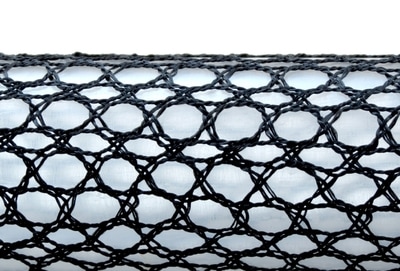

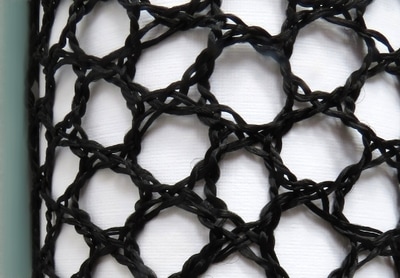

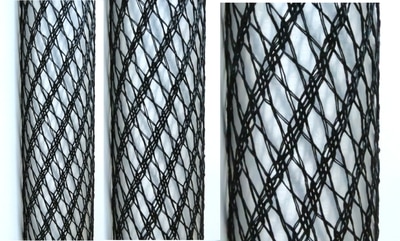

HYBRAID A textile crossbreed - combining the structural qualities of braided interlaced filaments and the resilience of knitted linked filaments, in the creation of multi-dimensional structures with intricately patterned, unbound lattice architecture that shape-shift with movement - distributing tensional forces. throughout the whole or within patterned zones.

|

|

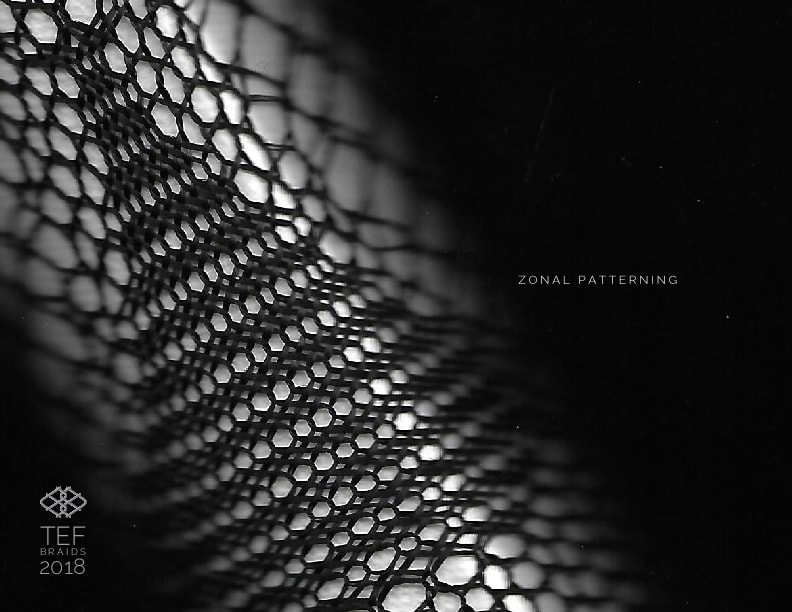

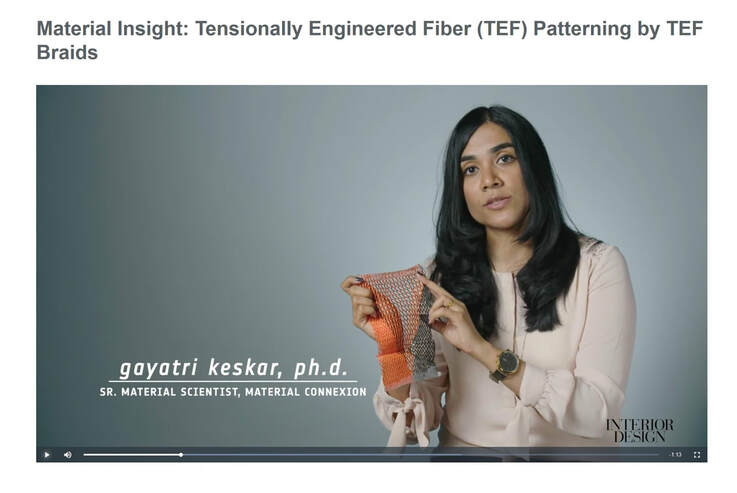

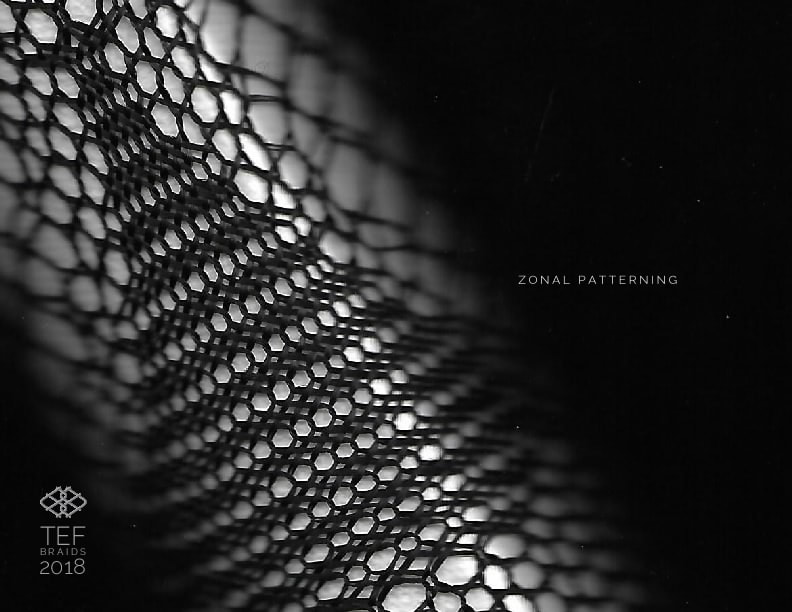

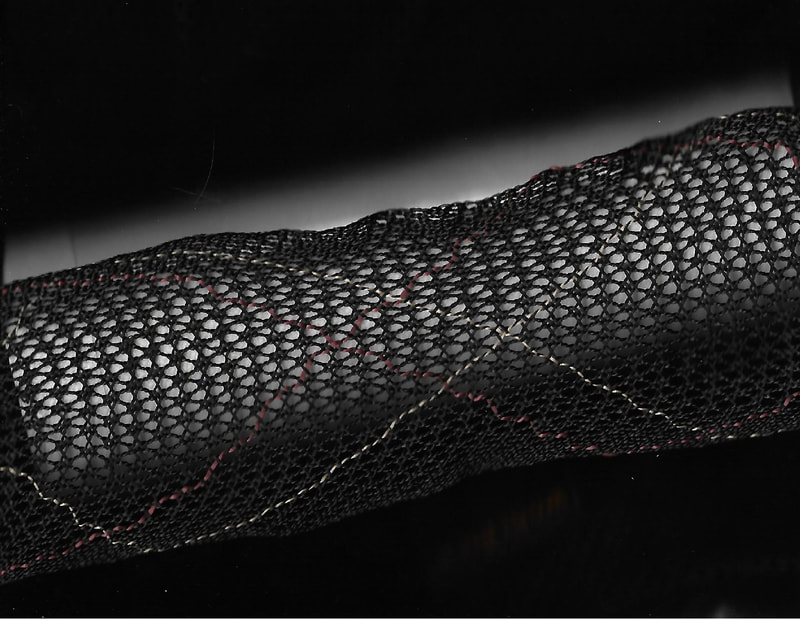

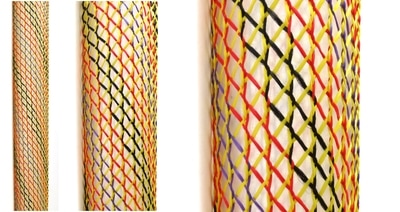

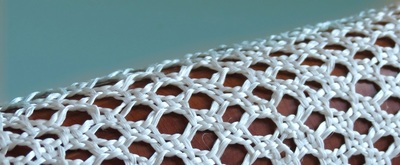

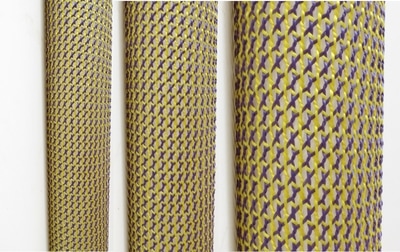

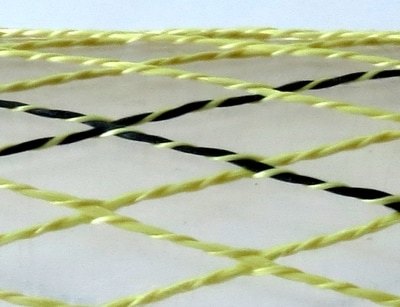

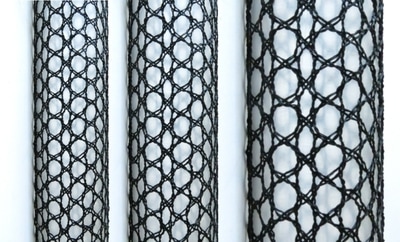

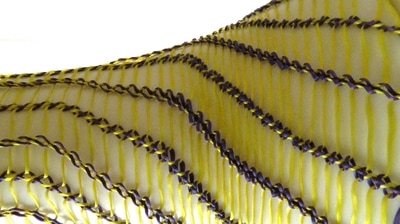

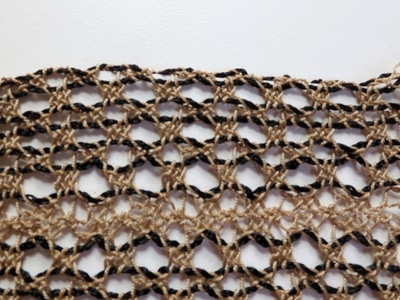

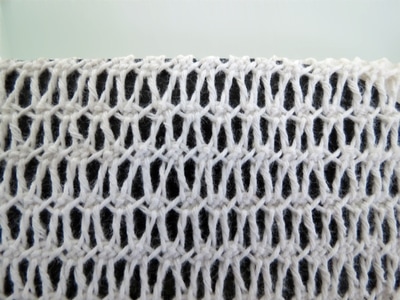

Advanced textiles are comprised of diversified zones with targeted characteristics. Predetermined areas are programmed to demonstrate a range of resistance, durability, compressibility, and breathability. Within a single form, TEF’s precise patterned, linked, and interlaced filaments integrate seamless and infinite variations in texture, density, support, and stretch.

|

Material ConneXion

|

|

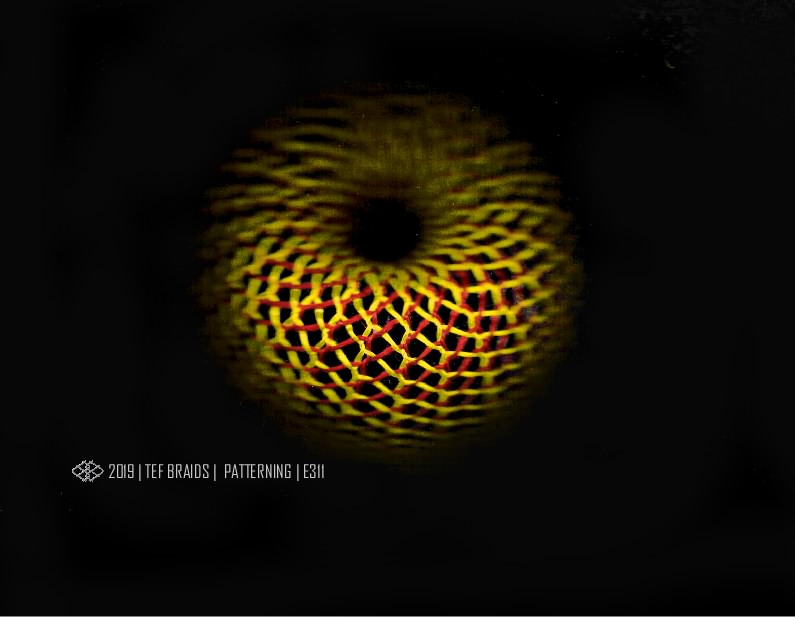

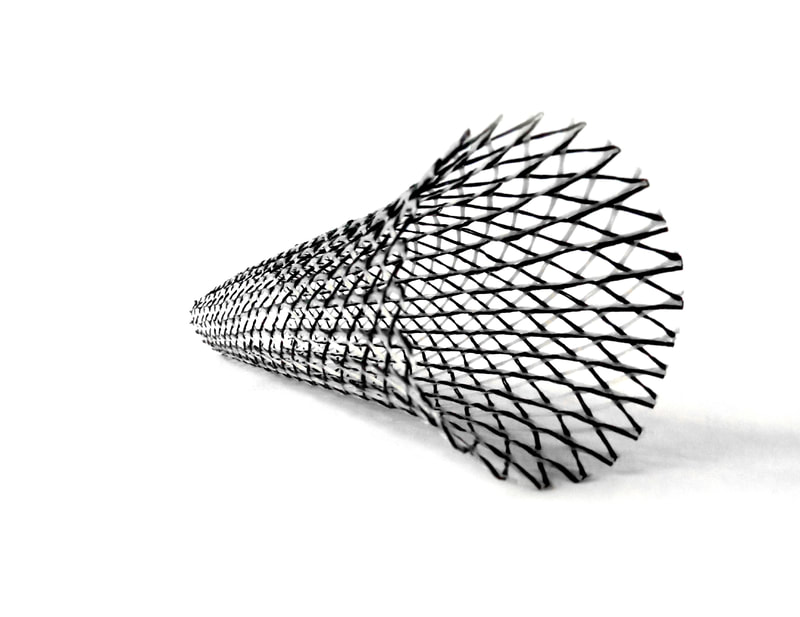

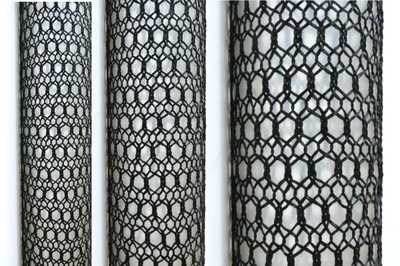

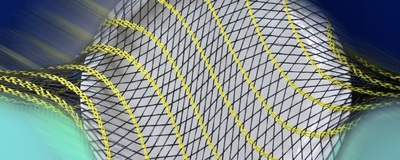

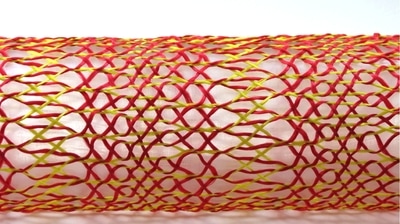

Lace Braiding Machines for Composite Preform Manufacture

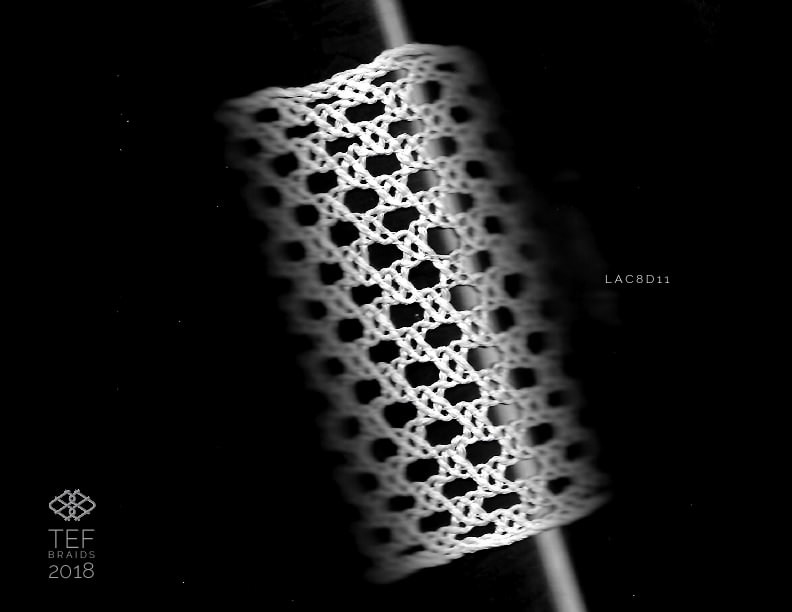

... However, one manufacturer currently offers engineered lace patterns for a myriad of applications including soft composites, sporting goods, and advanced apparel [1]. Several sources describe the esoteric nature and the lack of readily available design information

[2, 3]. Although, lace braiding machines have been used in medical applications and smart textiles [4]. David Branscomb, Yang Shen, Vladimir Quinones, Royall Broughton and David Beale (November 28th 2018). Lace Braiding Machines for Composite Preform Manufacture, Engineered Fabrics, Mukesh Kumar Singh, IntechOpen, DOI: 10.5772/intechopen.82256. |

Artemide

|

|

IP

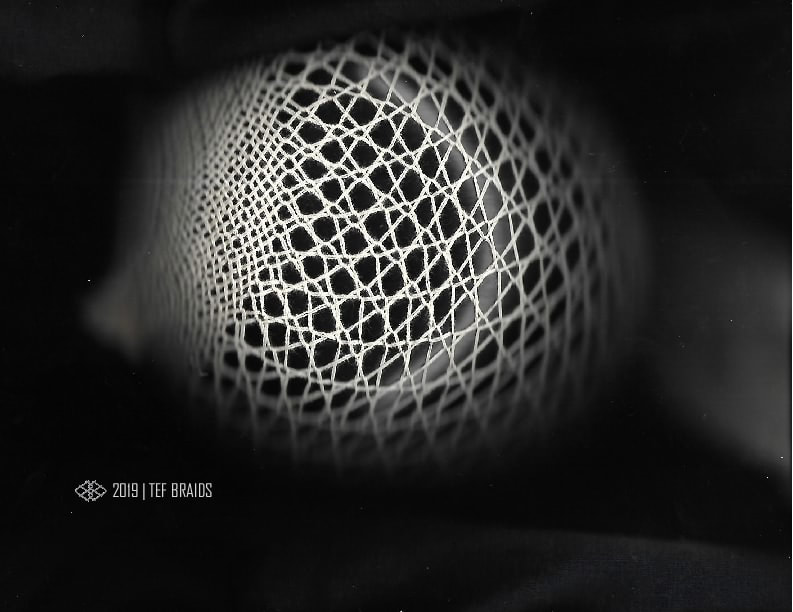

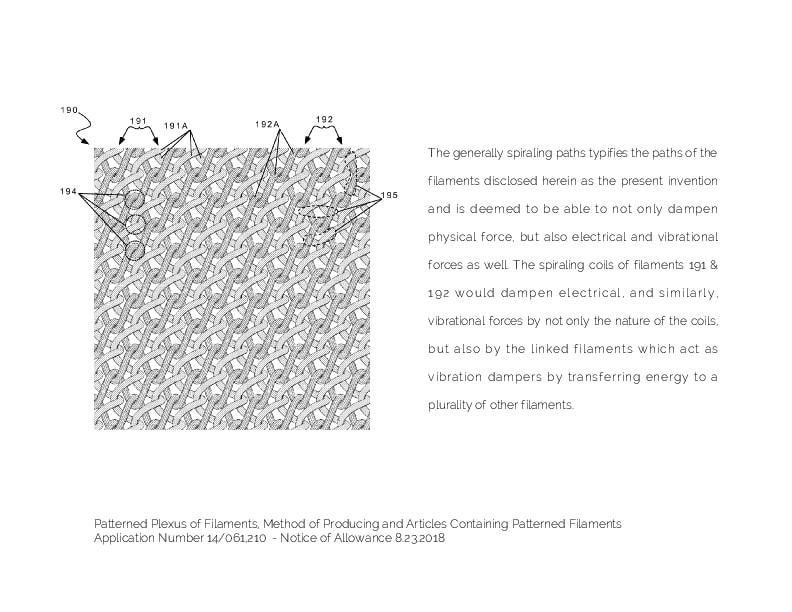

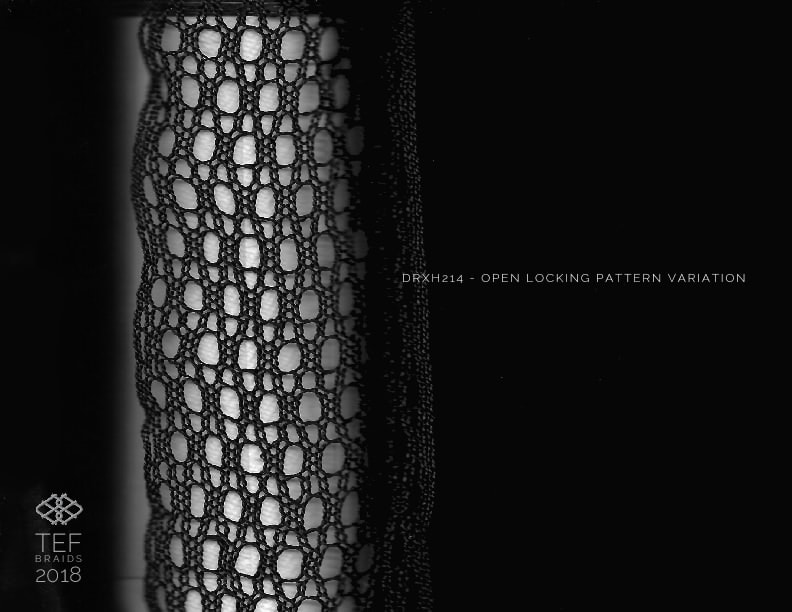

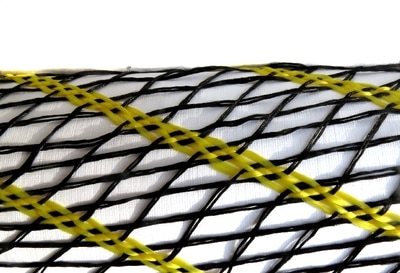

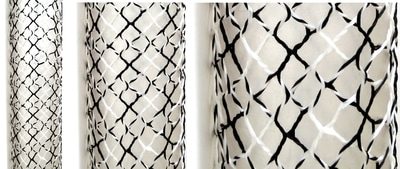

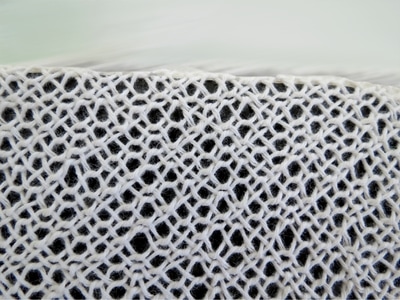

Multi-axial filament network comprising two sets of unified linked filaments that distribute tension between directionally opposed member -- merges seamlessly with a wide range of pattern variations -- generates material that is aesthetically unique, structural, flexible and conformal. US 10159297

INTELLECTUAL PROPERTY |

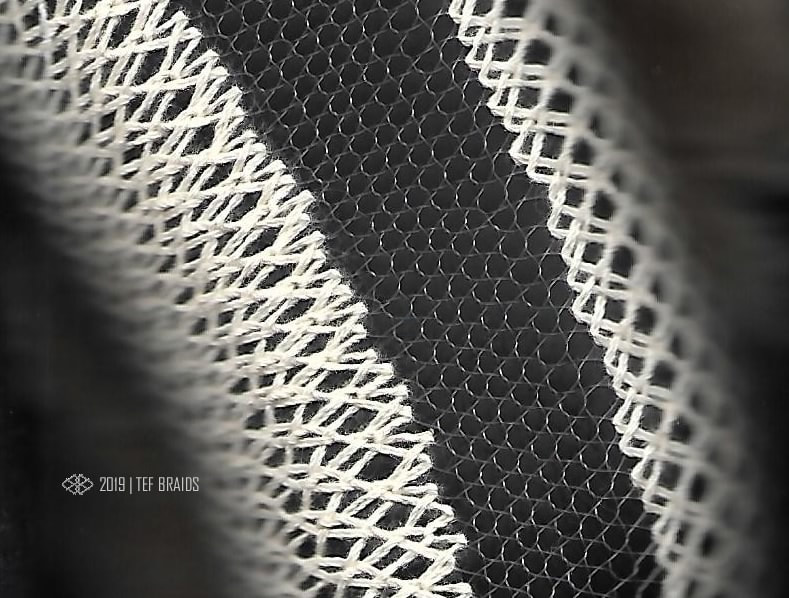

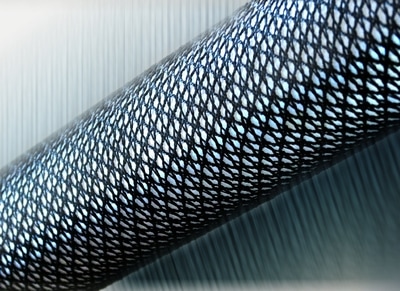

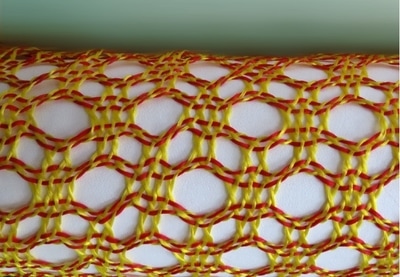

XhelX Pattern

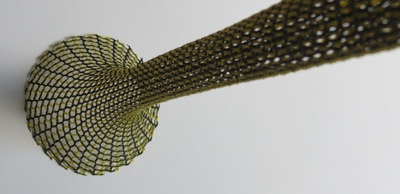

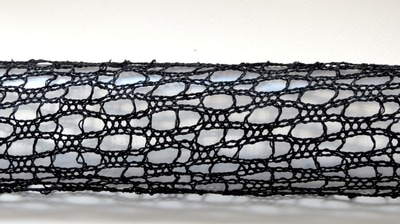

UNBOUND

Memory Mesh |

TEF's extraordinary fabrics have the capacity to expand up to 10x their diameter. Patterning can integrate logos, apertures, laces, and tags within the fabric.

|

|

BODYWEAR

Zonal Patternng Integrated Lacing Finishing DEVELOPMENT |

FOOTWEAR

|

BRAIDING

|

|

|

ZONAL

Patterning Integrated Conductive DEVELOPMENT |

|

TRUSS

|

|

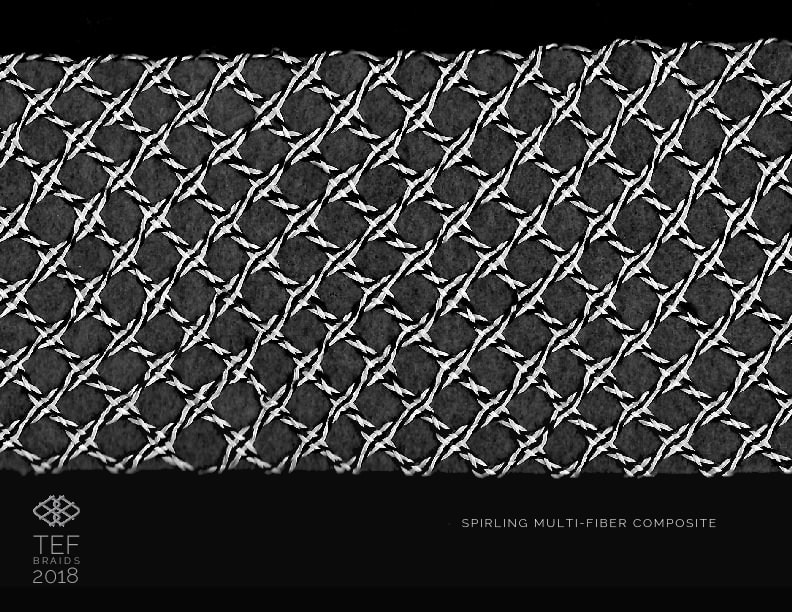

COMPOSITE

Flexible Impact Resistant DEVELOPMENT |

PATTERN GALLERY

|

|