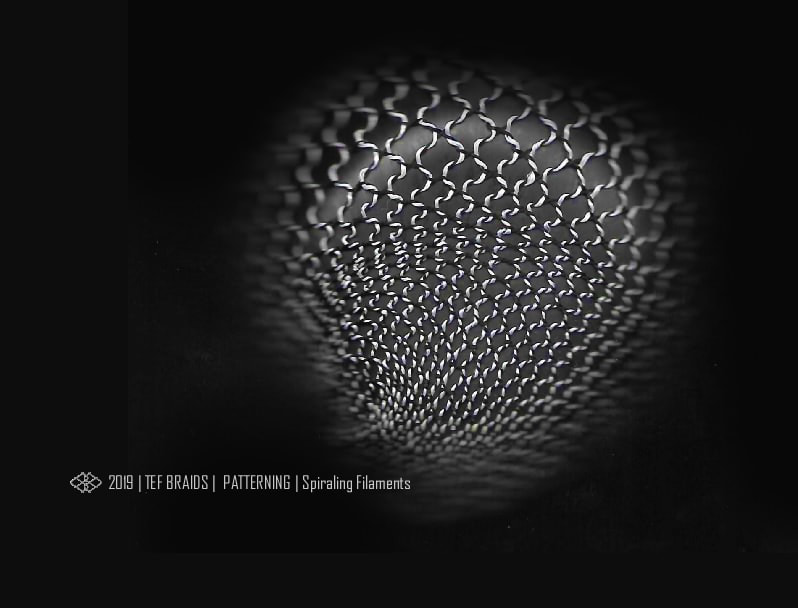

PATTERNING BASICS

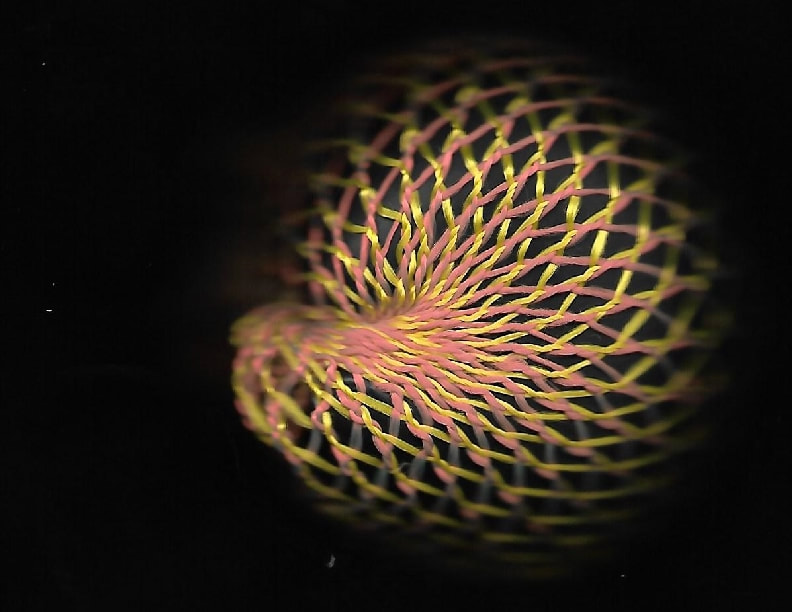

TEF's patterns are created through a sequence of linking and interlacing spiraling filaments. Sequential linking of spiraling filaments differentiates TEF fabrics from traditional braided materials that are interlaced. The linked filaments are fundamental to the dynamic behavior of TEF's textiles.

|

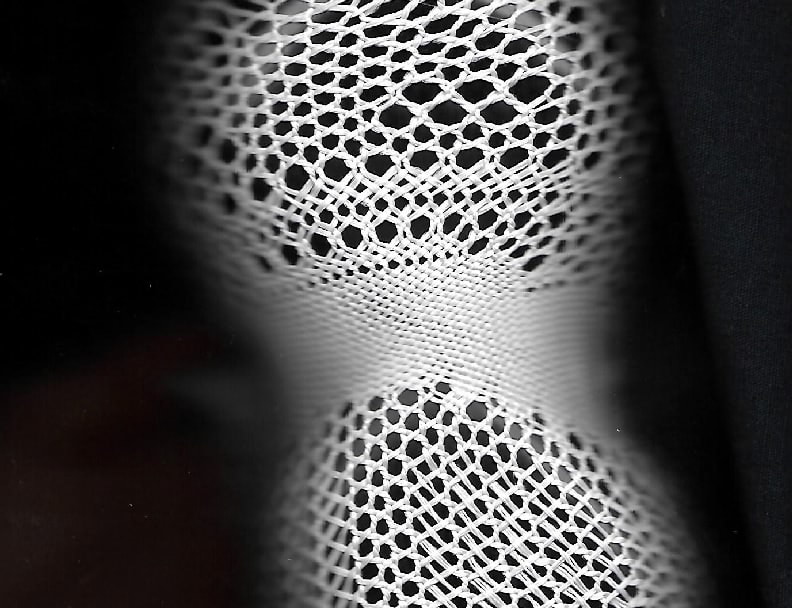

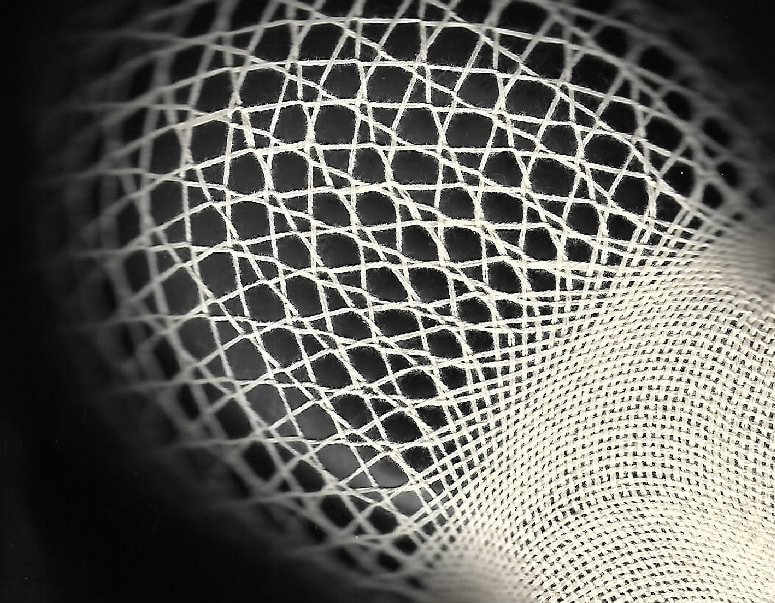

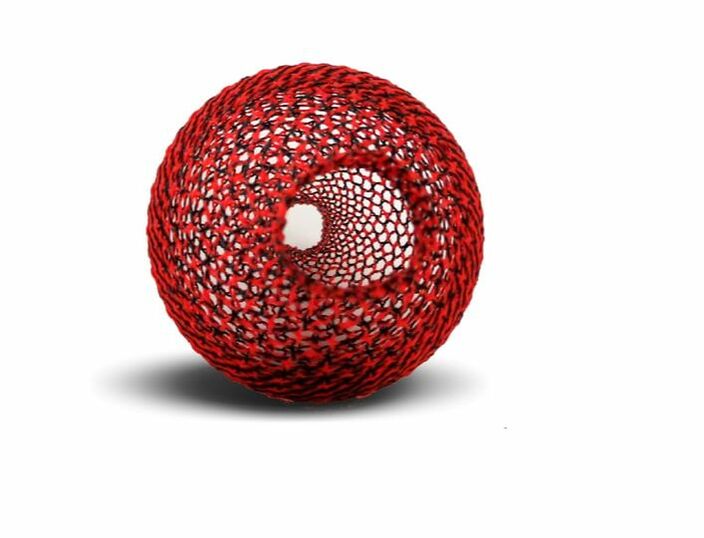

ZONAL PATTERNINGMechanically interlacing yarns in diverse sequences creates a tapestry of transitioning, patterned zones within an integrally and contiguously braided framework.

Diversified zones with targeted characteristics are integrated into seamless and infinite variations in texture, density, support, resistance, durability, and stretch. |

TENSION DISTRIBUTION

Zonally patterned fabric maintains the ability to distribute load tension throughout the structure due to continuous linked and interlaced fibers. Continuous, unbound filaments enable a structure to perform as one responsive, tension distributive, integrated whole.

Targeted tension distribution is advantageous for a broad range of applications, among them footwear and bodywear, where 360 degree tension stability enhances a products' performance. |

MATERIAL CHARACTERISTICS

TEF's most recent breakthrough patterns function similar to a hammock, creating a smooth distribution of tension provided by patterned duel helices comprised of spiraling filaments whose tensions are balanced against one another.

A hammock, (uni-directional linked spiraling filaments) is similar to patented XhelX pattern: two hammocks woven together at opposed angles, forming a multi-axial cross tension honeycomb structure - doubling load distribution and stability. |

FLEXIBLE COMPOSITES

TEF's transformative material offers an alternative to standard braids for zonally patterned, flexible and breathable composite structures. Patterned fabric provides a skeletal structure and foundation for a matrix that allows for geometrical changes within the fabric. Flexible composites are "softer" structures that integrate with, rather than resist forces.

|