|

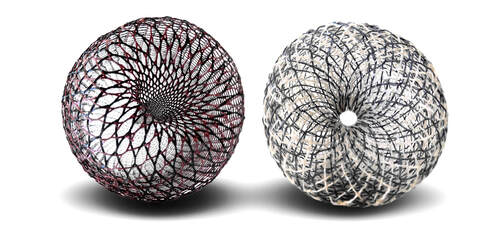

We use jacquard circular lace braiding machines to produce new fabrics that are made using proprietary ways of linking and interlacing yarns (patterns) as described in our patents:

Plexus of filaments with linked members Patterned plexus of filaments, methods of producing and articles containing patterned filaments |

Our first experiments with lace braiding comprised designing and testing 1000’s linked and interlaced patterns, then laid up into a composite structure using matrices with different qualities. We tested these patterns for impact resistance via hitting and batting an invention called Birdball (Play Device Patent ) in a game called Fair Game.

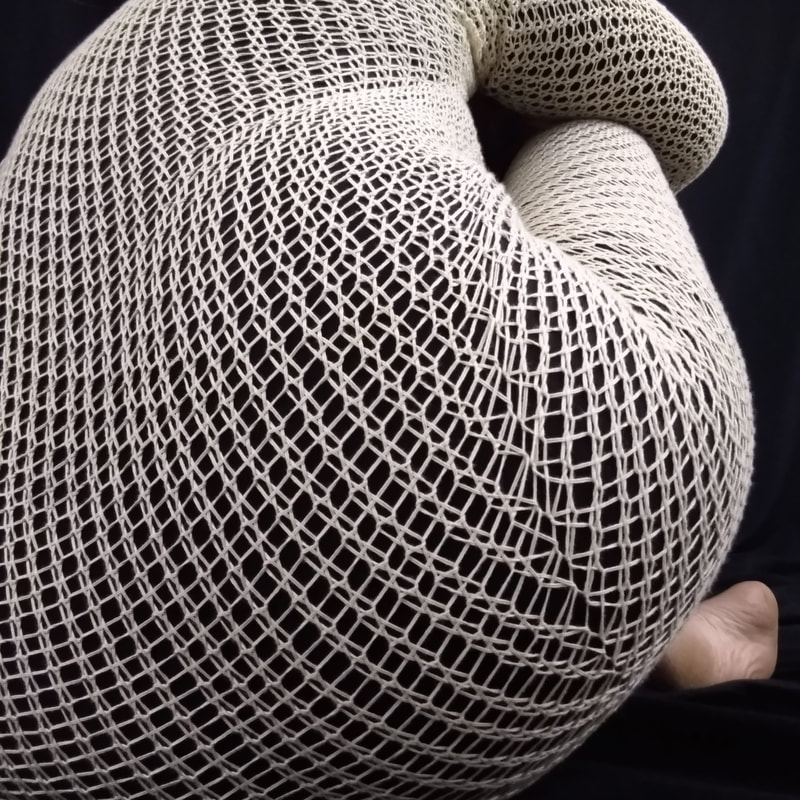

These experiments led to the invention of patterns that were impact resistant because of their ability to distribute tension in a balanced way in response to forces. When these fabrics were used in a dry state (without matrix), within a closed loop (unified structure) we found that the quality of self-balancing provided a low friction, non-rubbing, “stay-with-you” fabric that was comfortable and supportive. We applied this knowledge to footwear and bodywear.

|

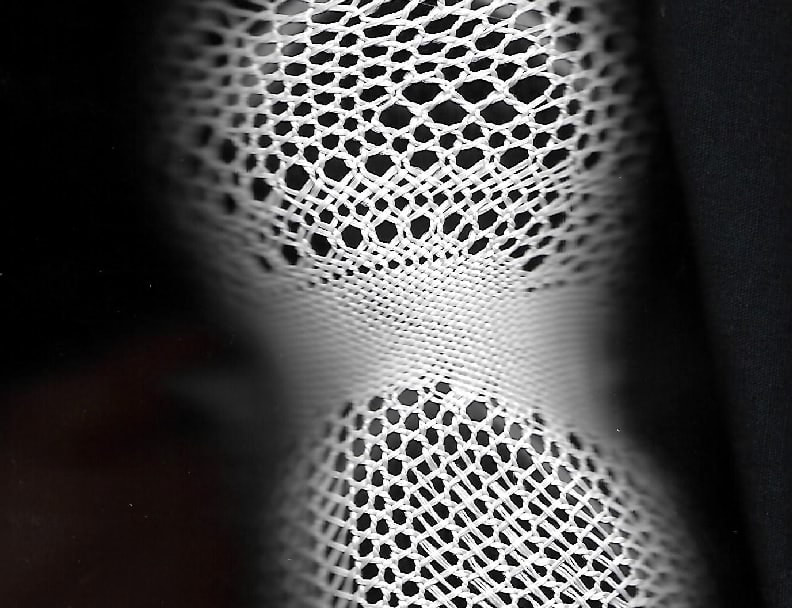

Most of our apparel is made with the ALX family of patterns. ALX makes programmable braiding possible because the pattern aligns with the movement of the spindles in a balanced way alleviating mechanical problems that are often the outcome of other patterns.

|

In essence, there is a balanced synergy between the way the yarns of ALX are linked and interlaced that allows the fabric to be produced. It took the development and testing of 1000’s of pattern tests to discover this synergy. |

|

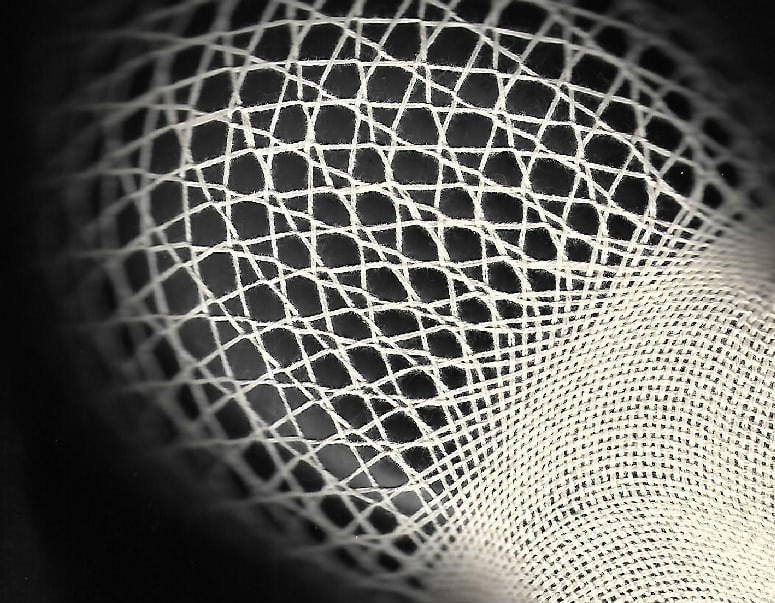

A conformal, fluid "exo-skeleton" with a controlled surface texture may provide a “fish scale” or “feather” advantage. This same exo-skeleton could be used as a patterned textural “skin” on the surface of rigid braided composite structures for industrial applications such as airplane wings and wind turbines.

|

In reverse, a patterned internal skeletal structure incorporated with a "skin" could provide a zero waste, efficient way to manufacture products that mimic anatomy's performance.

|