|

Sustainability Priority & Purpose

New ways of manufacturing that use less material and energy while also producing high performance products that are aesthetically intriguing is the objective. The design and manufacture of adaptable, unified constructions that prioritize efficiency and longevity bring us closer to sustainability goals and provide a meaningful purpose for the creation new products. |

TEF Braids and Tensengral have chosen to make bodywear to showcase the many and diverse benefits of the programmable braiding and Tensengral patterning technology. In particular we've focused on the development of bras - an essential item that historically has seen little change in design and function.

In an industry where brand after brand are claiming to ‘reinvent’ the bra simply by removing the underwires, it’s refreshing to come across a lingerie company that’s actually doing something new and different. New York-based Tensengral has merged together antique and modern technology to create a whole new type of lingerie fabric, one they describe as “performance lace”. |

AMBI is an every day, every occasion 24/7 wear anywhere/everywhere bra for every age and body.

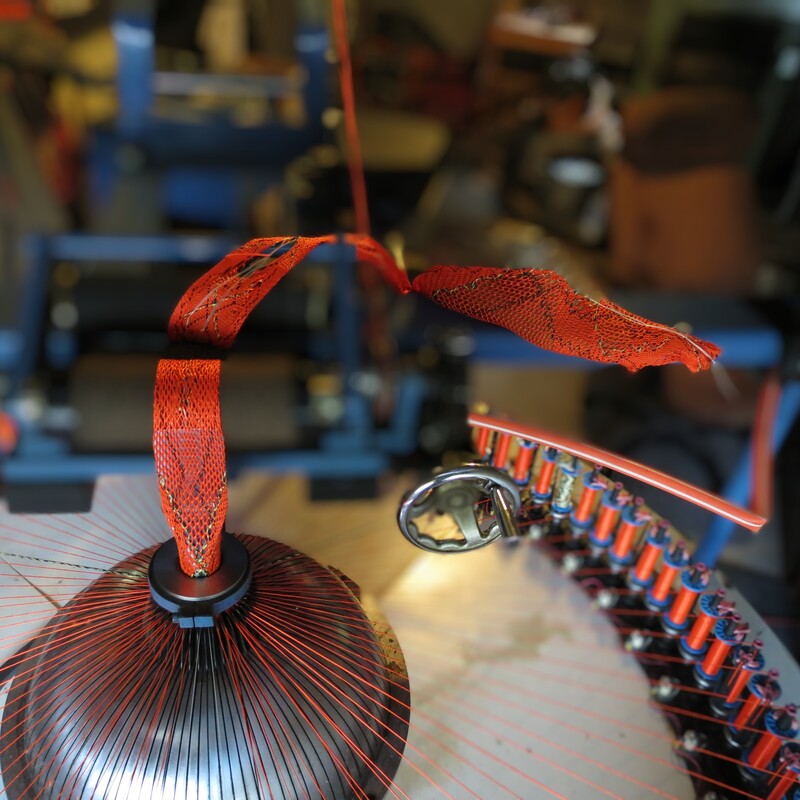

AMBI is the world’s first-ever bralette, crafted using yarns that are braided vs. knit or woven. AMBI has a refined 'boho' aesthetic that is rich in texture. The self-organizing yarns of AMBI's conformal fabric naturally adapt to an individual's breast and body shape providing a new fit and feel experience that is almost invisible. Each AMBI bralette is artisan-designed and individually crafted on re-purposed vintage lace-making machines by talented makers in upstate New York, USA,

AMBI is the world’s first-ever bralette, crafted using yarns that are braided vs. knit or woven. AMBI has a refined 'boho' aesthetic that is rich in texture. The self-organizing yarns of AMBI's conformal fabric naturally adapt to an individual's breast and body shape providing a new fit and feel experience that is almost invisible. Each AMBI bralette is artisan-designed and individually crafted on re-purposed vintage lace-making machines by talented makers in upstate New York, USA,

|

Aesthetic

A 'boho' aesthetic, refined but still with a sense of interesting and intriguing craftsmanship. Simple and sleek, yet rich in texture. |

Style

AMBI is a simple pull-on style that naturally adapts to many individual body/breast shapes. |

Design

Unique 1-piece ‘braided lace’ (not knit or crochet) construction that automatically (magically!) adjusts and personalizes fit and support in ways a knit or woven bra just can’t do. |

|

Function

On-body, the yarns self-organize to become more ‘dense’ in covering/disguising underlying breast tissue for modesty, more open in torso zones where ventilation is desirable. |

Feel

AMBI has been described as feeling almost invisible and "quietly" supportive. The mesh material "stays with you" and "magically" adjusts with your movements. |

Comfort

AMBI’s unique braided construction gives unparalleled comfort, fit and breathability to a wide range of body sizes and types. |

|

Support

When the bra is on-body under tension, its braided structure actually becomes more firm/less extensible for increased support in key zones. |

Ingredients

Earth-and body-friendly yarns: a natural cream-colored mix of Tencel (made from sustainably-harvested eucalyptus wood pulp using recyclable non-toxic solvents) and U.S. grown Supima cotton, one of the softest and strongest forms of cotton. |

Sustainability

Super-sustainability! The only bra on the market manufactured with virtually zero-waste, with none of the fabric scraps that result from cutting the many oddly-shaped pieces that go into a regular bra. |

|

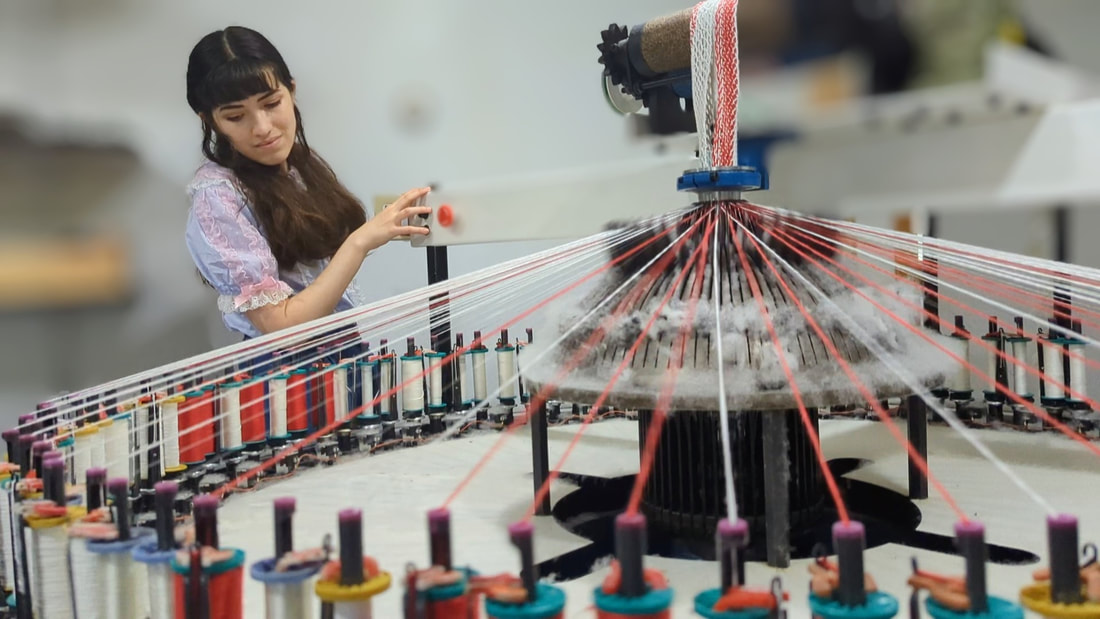

Efficient, Virtually Zero Waste Manufacturing Process

Heritage jacquard lace braiding machines that have been reconfigured with electronic controls for use with computer aided design systems provide the means of production for this new efficient way of making things. The addition of CAD to these century-old machines opened the door for production of fabrics that merge variable zones of support and structure within a single unified piece of fabric. These different zones impart qualities with different performance values and eliminate the need for pieced together, disjointed product constructions. This way of making things allows for a virtually zero waste manufacturing paradigm because function is built into a single piece of fabric during the one-step manufacturing process. |

|

Development of New Fabrics

We use jacquard circular lace braiding machines to produce new fabrics that are made using proprietary ways of linking and interlacing yarns (patterns) as described in our patents: Plexus of filaments with linked members Patterned plexus of filaments, methods of producing and articles containing patterned filaments Different patterns within these families of patented patterns can be merged to achieve varying qualities within the fabric. These different pattern orientations (zonal patterning) can be achieved through programming (CAD) the spindles on the machine to move forward, backwards or not move at all.

|

Personalized Fit and Function

AMBI's unique 1-piece ‘braided lace’ (not knit or crochet) construction automatically (magically!) adjusts and personalizes fit and support in ways a knit or woven bra just can’t do. AMBI also brings the sensibility of a simple, pull-on style that naturally adapts to many individual body/breast shapes. When the bra is on-body under tension, its braided structure actually becomes more firm/less extensible for increased support in key zones. On-body, the yarns self-organize to become more ‘dense’ in covering/disguising underlying breast tissue for modesty, more open in torso zones where ventilation is desirable.

AMBI's unique 1-piece ‘braided lace’ (not knit or crochet) construction automatically (magically!) adjusts and personalizes fit and support in ways a knit or woven bra just can’t do. AMBI also brings the sensibility of a simple, pull-on style that naturally adapts to many individual body/breast shapes. When the bra is on-body under tension, its braided structure actually becomes more firm/less extensible for increased support in key zones. On-body, the yarns self-organize to become more ‘dense’ in covering/disguising underlying breast tissue for modesty, more open in torso zones where ventilation is desirable.

|

Comfort

"Comfort-based wardrobes are the new normal; looking polished while being comfortable is key. To the modern consumer, buying a comfort apparel product is also a moment of self-care.” AMBI’s unique braided construction gives unparalleled comfort, fit and breathability to a wide range of body sizes and types. |

|

Material Choices known for the Circularity and Longevity

The beauty of programmable braiding is its versatility and ability to integrate many different filament types to achieve diverse performance objectives. For AMBI we've chosen to use Earth-and body-friendly yarns: a natural cream-colored mix of Tencel (made from sustainably-harvested eucalyptus wood pulp using recyclable non-toxic solvents) and U.S. grown Supima cotton, one of the softest and strongest forms of cotton. |

|

Artisan-created

In tandem with sustainability is a desire for a connection with lower-tech, artisan-made products in an increasingly virtual world, knowing by whom, how and under what circumstances a product was created, and backing up that value with an informed purchase decision. AMBI’s designer/maker story is authentic, powerful and compelling. |

|

Partners

TEF Braids and Tensengral seek to further develop the technology and products with partners from many different categories as well as train others in using the technology so that they can develop their own products. AMBI is the first product that we are ready to bring to the market-place, or, into a collaboration that is meant to improve upon/customize an existing product. Just as The Frayme Mylo launched with a limited edition run with Stella McCartney's support as part of her "conscious luxury movement", we wonder if a similar sort of collaboration is feasible for Tensengral, to allow time for us to grow with the benefit of adequate resources to devote to ongoing development and production operations, and, as a consequence of affiliation, well-rounded media attention as to the "sustainability" aspects of the technology and its diverse applications. |